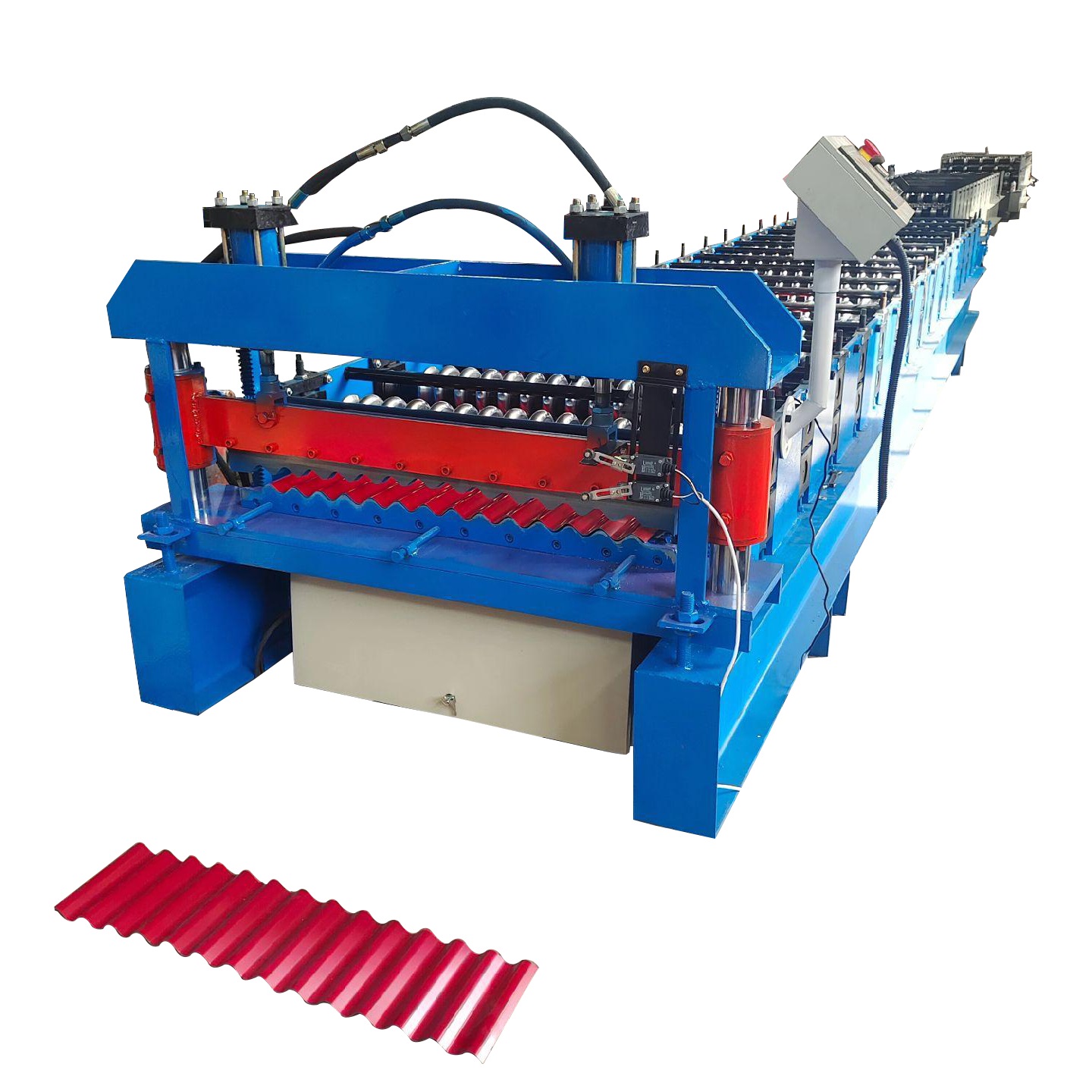

Equipment display

PLC Automatic Control Stable Structure & Long Service Life

Custom Roof Tile Profiles Available High Precision Rollers

Main components of roof tile forming machine

Key Advantages

Why choose our roof tile roll forming machine?

-

-

-

High Precision Forming

CNC-machined rollers ensure accurate roof tile shapes

-

Automatic PLC Control

Easy operation with automatic length setting and cutting

-

Strong & Stable Frame

Heavy-duty structure ensures long-term stable production

-

Profile Customization

Roof tile profiles can be customized based on drawings

Applications

Customization Options

-

-

-

Roof tile profile design support

-

Sheet width and thickness customization

-

Forming speed and motor power adjustment

-

Voltage and electrical standards

-

Brand logo and machine color customization.

Production Quality Control & After-Sales Service

-

-

-

Trial run before shipment

-

Finished tile sample confirmation

-

Test video provided

-

Installation guidance and operation manual

-

Online technical support

-

Spare parts supply

-

Warranty service

FAQ

-

-

-

What materials can the roof tile roll forming machine process?

-

Can roof tile profiles be customized?

-

How long is the delivery time?

-

Do you provide installation support?

-

Get a Quote | Send Inquiry Now