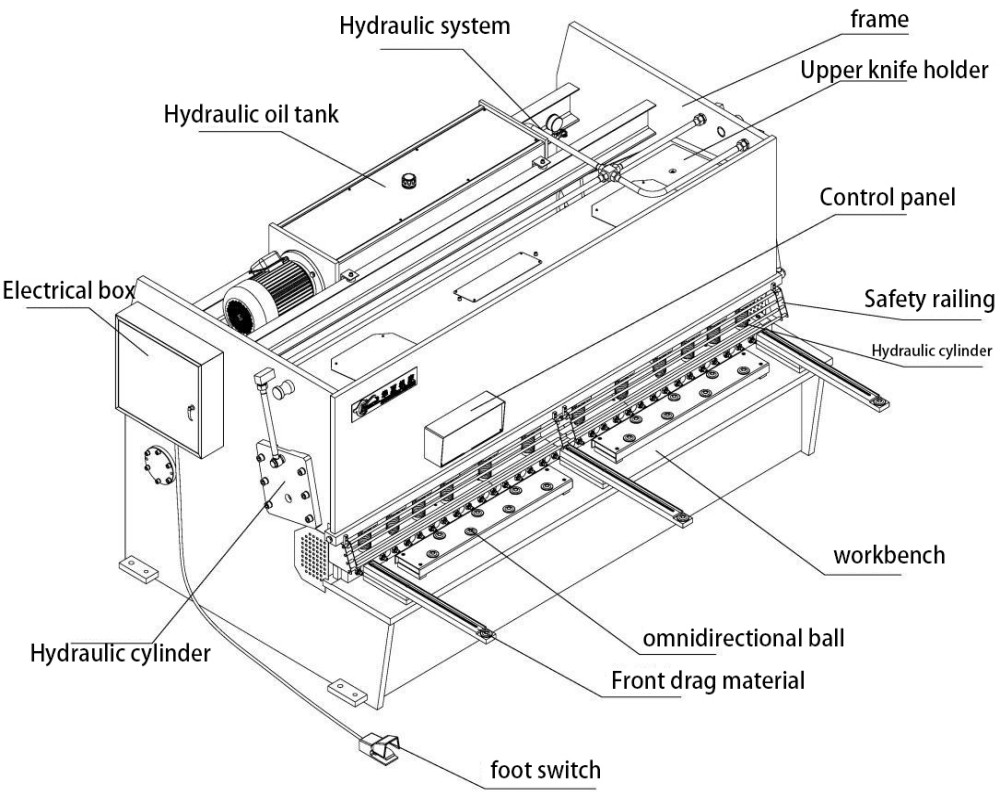

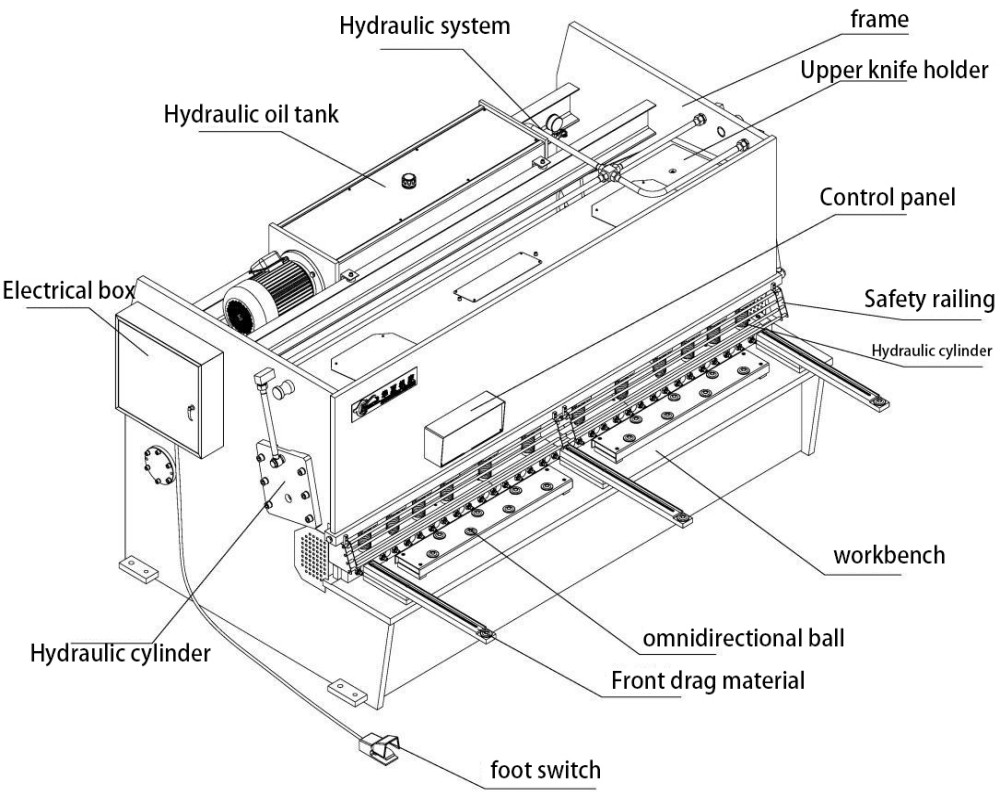

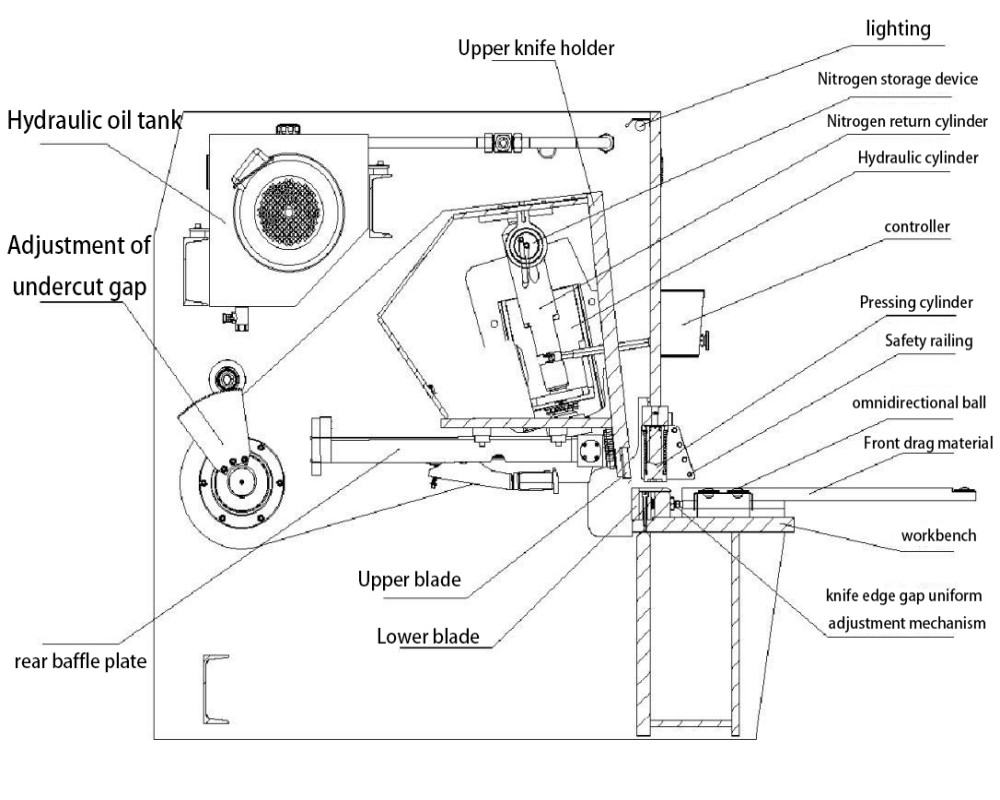

External structure

1. All-steel structure design and fabrication, aesthetically pleasing and structurally reliable.

2. Utilized UG (Finite Element Method) analysis and computer-aided optimization design.

3. Integral welded steel plate structure, possessing excellent strength, rigidity, and vibration resistance. Two cylinders are fixed to left and right columns. An auxiliary tool holder is provided on the worktable for easy fine-tuning of the blades. Feeding rollers are also installed on the worktable for convenient operation.

4. Vibration aging technology is used to eliminate internal stress.

5. The entire frame is sandblasted to remove rust and then coated with anti-rust paint.

Machine Display

Performance characteristics

1. The blade gap is adjustable to accommodate different plate thicknesses and materials.

2. The upper and lower blades can be used with two or four cutting edges. They are made of high-quality materials to improve wear resistance and service life.

3. The upper blade holder adopts an inward tilting structure for easier material unloading and improved workpiece accuracy.

4. Adjusting the shearing stroke can improve processing efficiency and enable segmented shearing.

5. An automatic counting function is included to reduce tedious counting work.

6. All parts are rationally designed for easy operation; key parts require lubrication every shift.

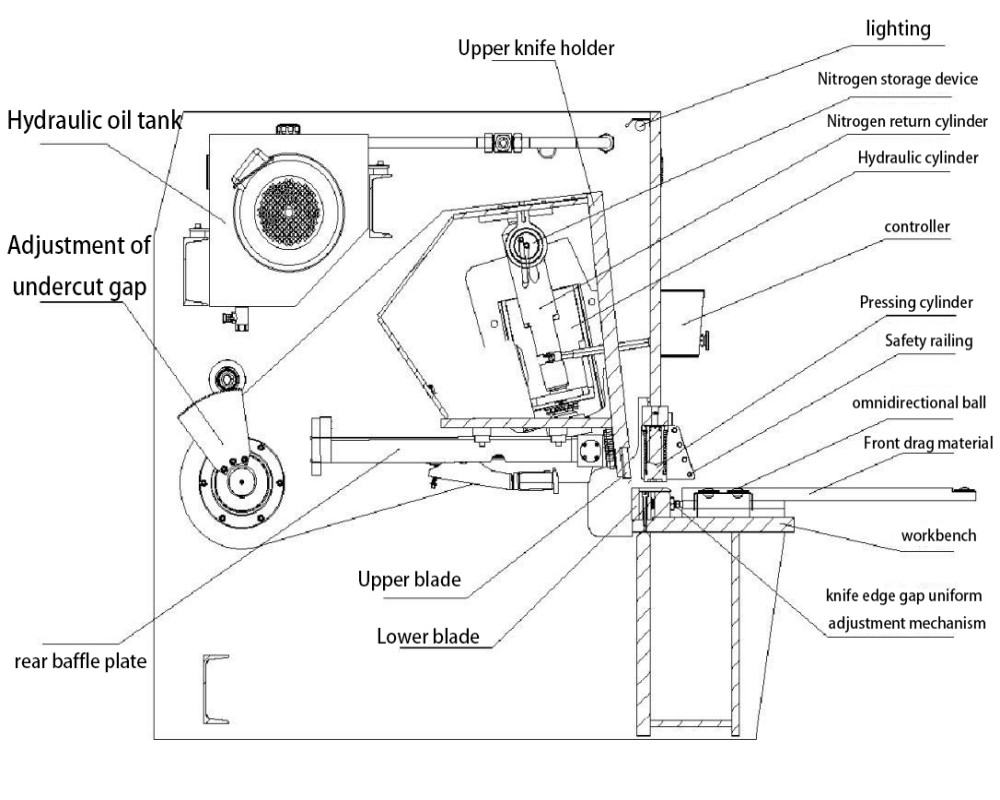

Hydraulic system

1. An advanced integrated hydraulic system is adopted, reducing pipeline installation and ensuring high reliability and safety during machine operation.

2. A hydraulic pressing mechanism is used. After oil is supplied to several pressing cylinders mounted on the support plate at the front of the machine frame, the pressing head presses down against the tension of the spring, clamping the sheet material. After shearing, it returns to its original position by the tension of the spring. The magnitude of the pressing force increases with the increase of the thickness of the sheet being sheared.

Electrical Control System

1. Electrical components and materials conform to international standards, ensuring safety, reliability, and long service life.

2. This machine uses a 50Hz, 380V three-phase four-wire power supply. The machine motor uses three-phase 380V, and the control transformer uses two-phase 380V. The output of the control transformer supplies power to the control circuit, with 24V used for back gauge control and the solenoid directional valve.

6V supplies indicator lights, and 24V supplies other control components.

3. The electrical box is located on the left side of the machine tool. Except for the foot switch, all operating components are concentrated on the button station at the front of the machine tool. The function of each operating component is indicated by a symbol above it.

Core components

Main motor

Uses a renowned brand motor with a national standard all-copper core,features low noise and a long service life.

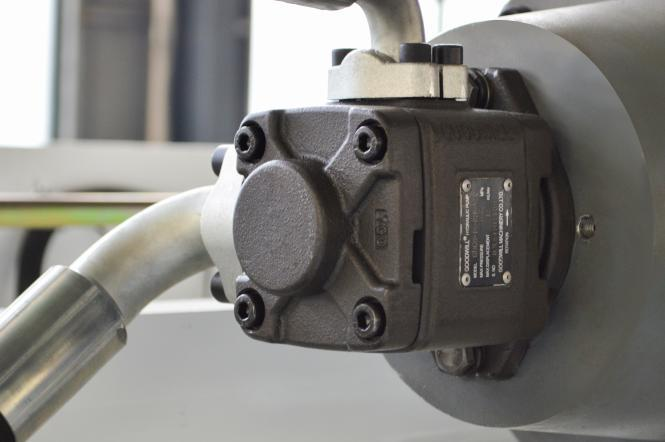

High-pressure oil pump:

Adopts high-performance oil pumps from well-known domestic brands, with high volumetric efficiency, small flow and pressure fluctuations, and low noise.

Hydraulic Valve Assembly:

The hydraulic valve assembly uses well-known Jiangsu Jianhu brand (German Rexroth is optional), and adopts an advanced hydraulic control system, which is efficient and highly accurate.

Oscillating Structure

A well-designed oscillating structure for the tool holder relies on a hydraulic transmission system. Through the cooperation of components such as hydraulic cylinders, the return stroke is achieved. During the return stroke, the tool holder oscillates in an arc around a fixed axis.

Gap Adjustment

The gap between the upper and lower blades can be adjusted by rotating the handle, suitable for shearing different sheet thicknesses. An indicator light shows the adjustment process, which is easy, quick, and stepless.

Key Advantages

Years of experience in metal processing equipment manufacturing.

Mature and stable QC12K series products.

Strict factory testing to ensure stable operation of every machine.

Supports multiple specifications and models as well as customization needs.

Provides professional after-sales and technical support.

Get a quote

📩Click here to contact us now