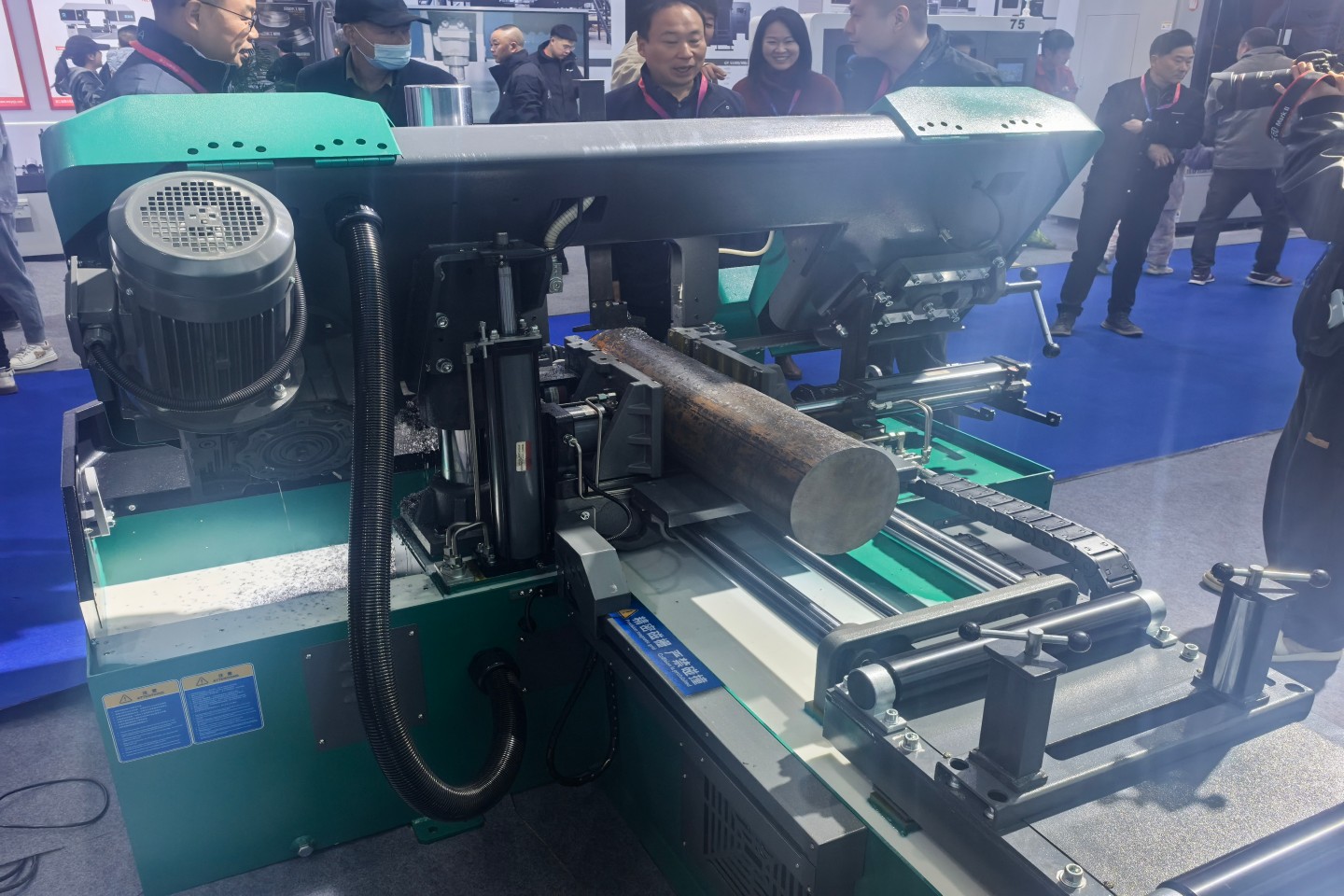

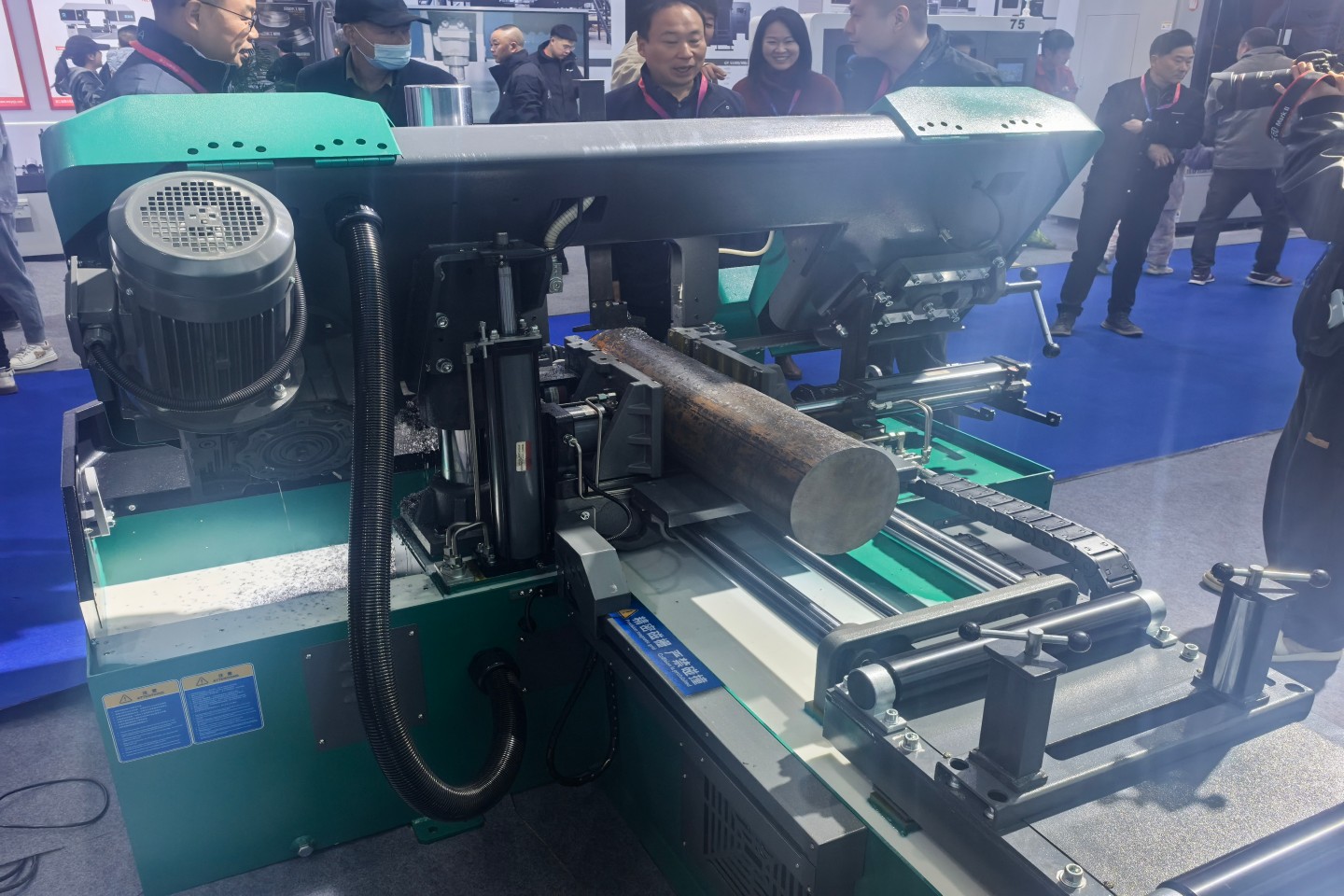

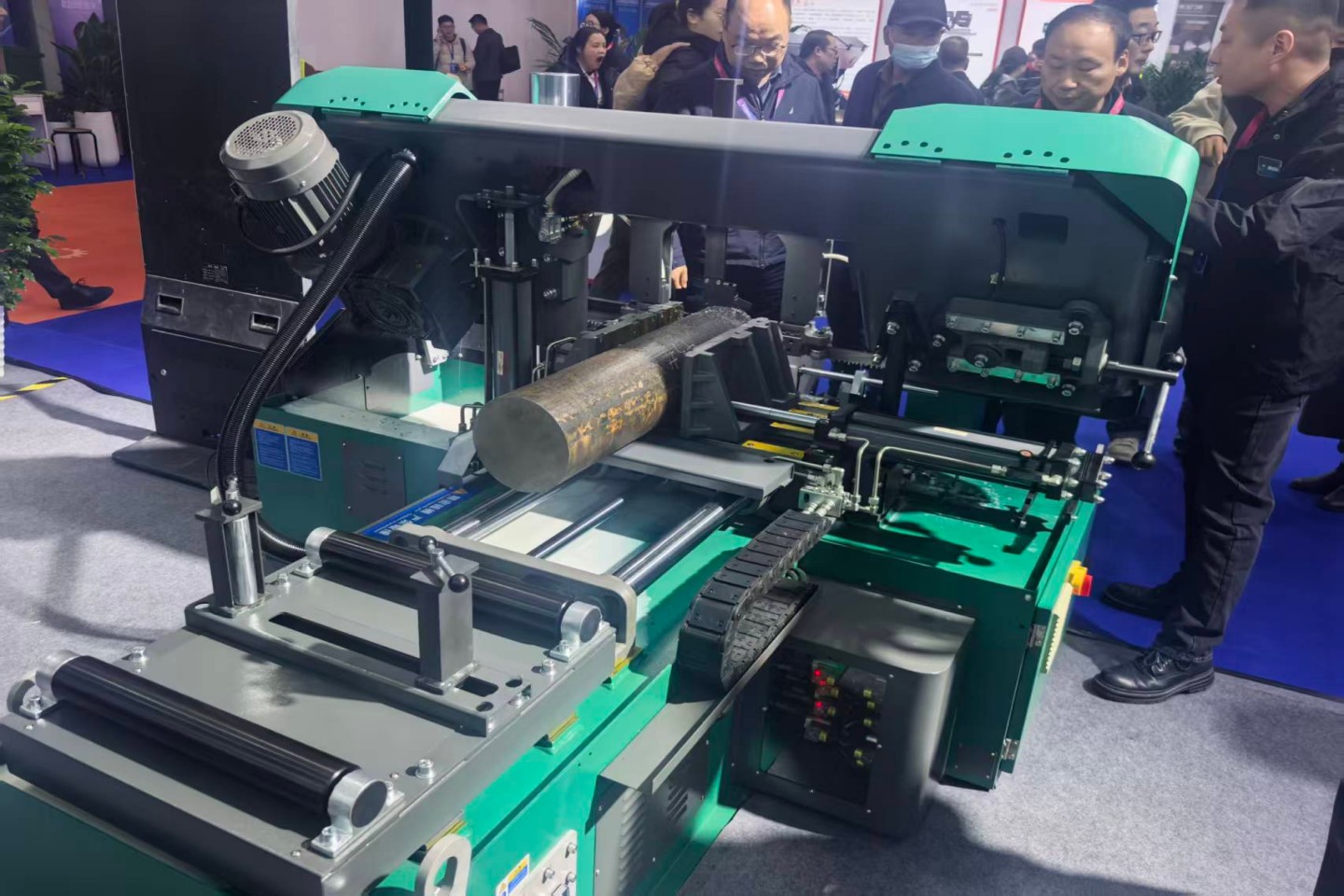

Equipment display

Metal Material Cutting

Carbon steel, stainless steel, alloy steel

Aluminum, copper, and other non-ferrous metals

Profiles (H-beams, I-beams, channel steel, angle steel)

Pipes, solid round steel, square steel

High cutting precision

Straight cuts, minimal burrs

Good dimensional consistency, reducing secondary processing

High efficiency, material saving

Narrow kerf, low material waste

Suitable for continuous cutting and batch production

Wide cutting range

Can cut large cross-sections and large diameter workpieces

Suitable for solid materials and thick-walled materials

Good safety and stability

Smooth cutting process with minimal vibration

Less sparks compared to abrasive wheel cutting, making it safer

Machine Details

Rigid frame enables vibration-free cutting

Precision guide system ensures smooth, straight cuts

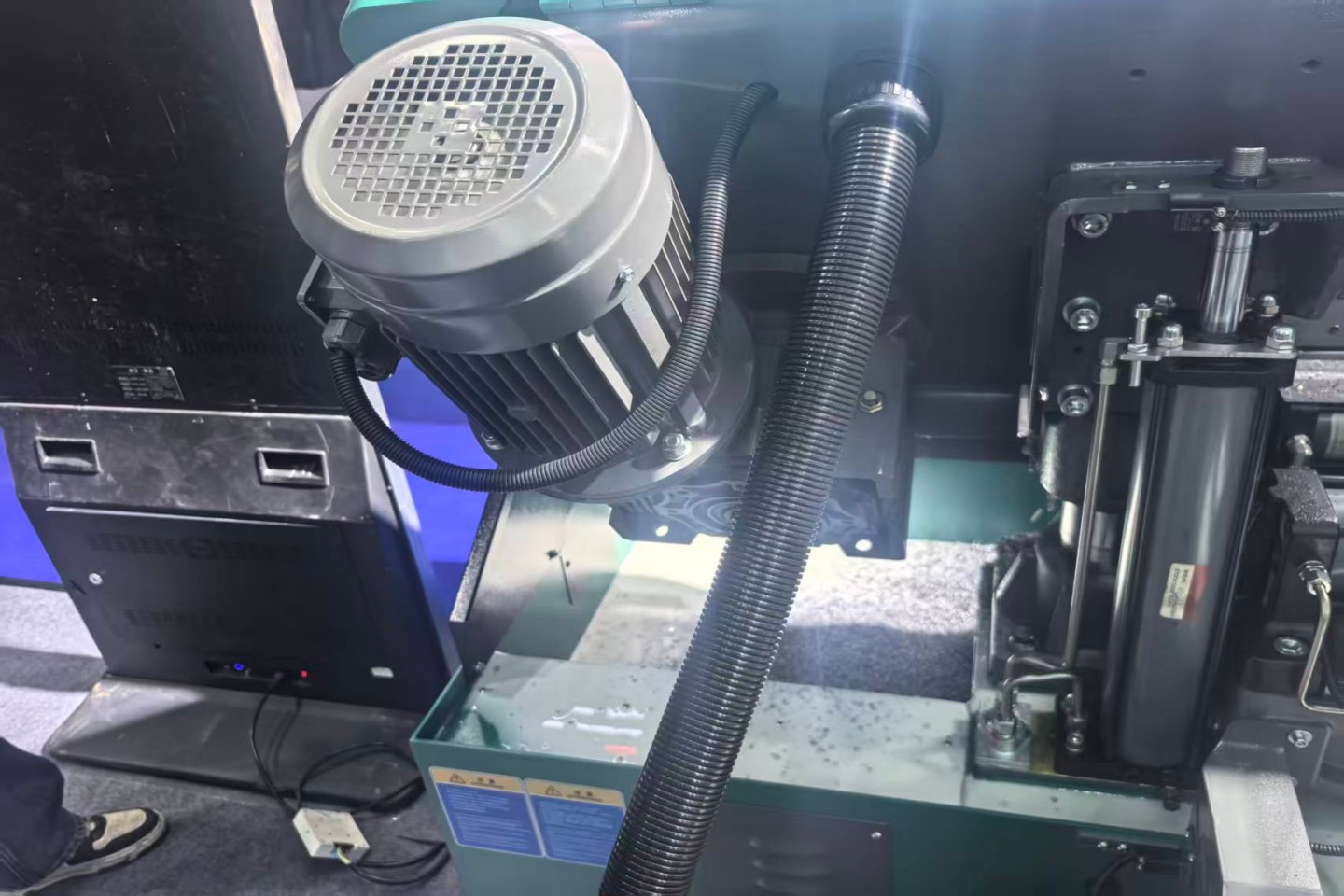

Main motor and transmission device

Adopting a direct-drive reducer, the cutting power output is direct, the transmission efficiency is higher, and the sawing speed is increased by 15% across the board.

Touch Panel

The system combines an intelligent touch-screen human-machine interface with physical buttons for more convenient machine control.

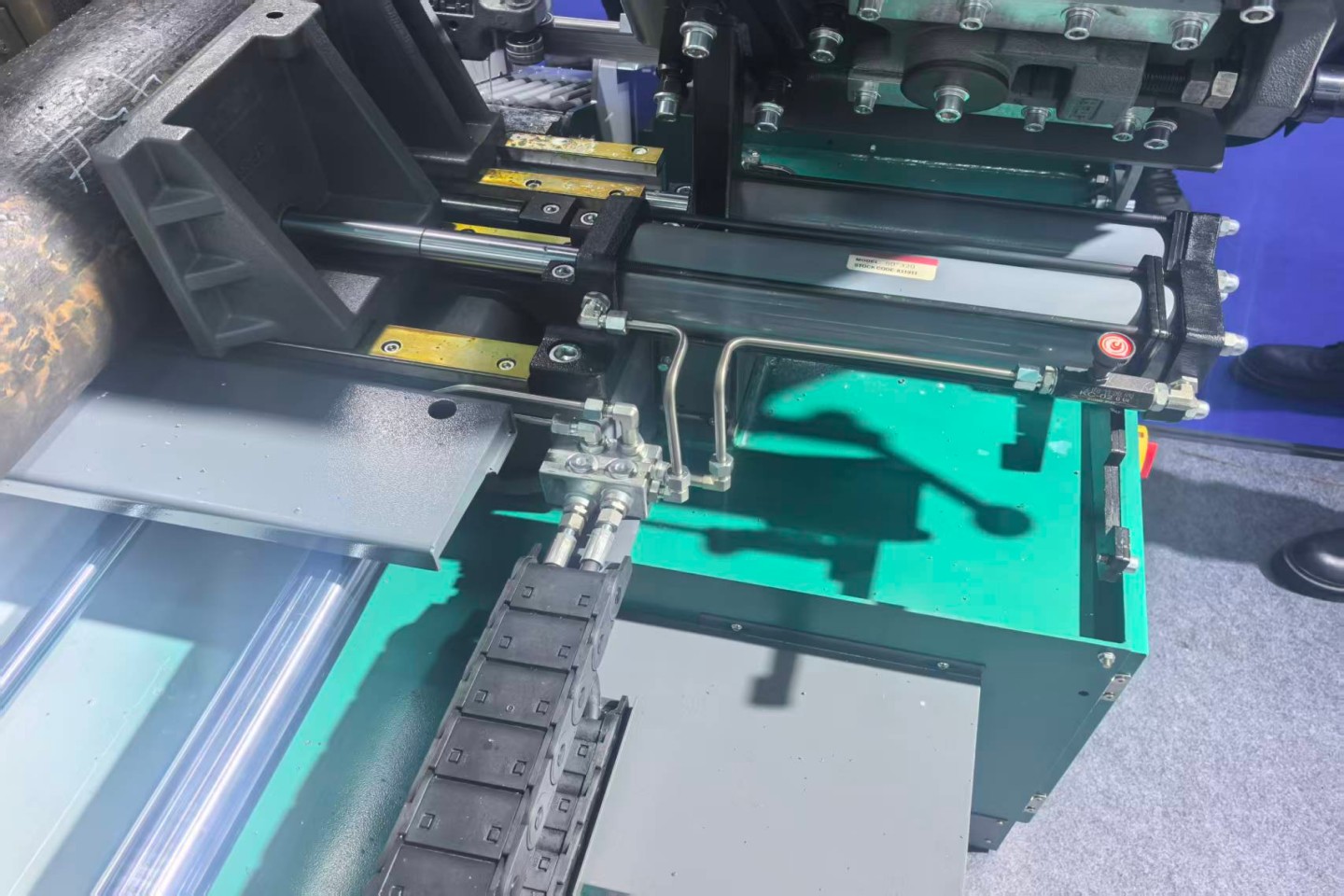

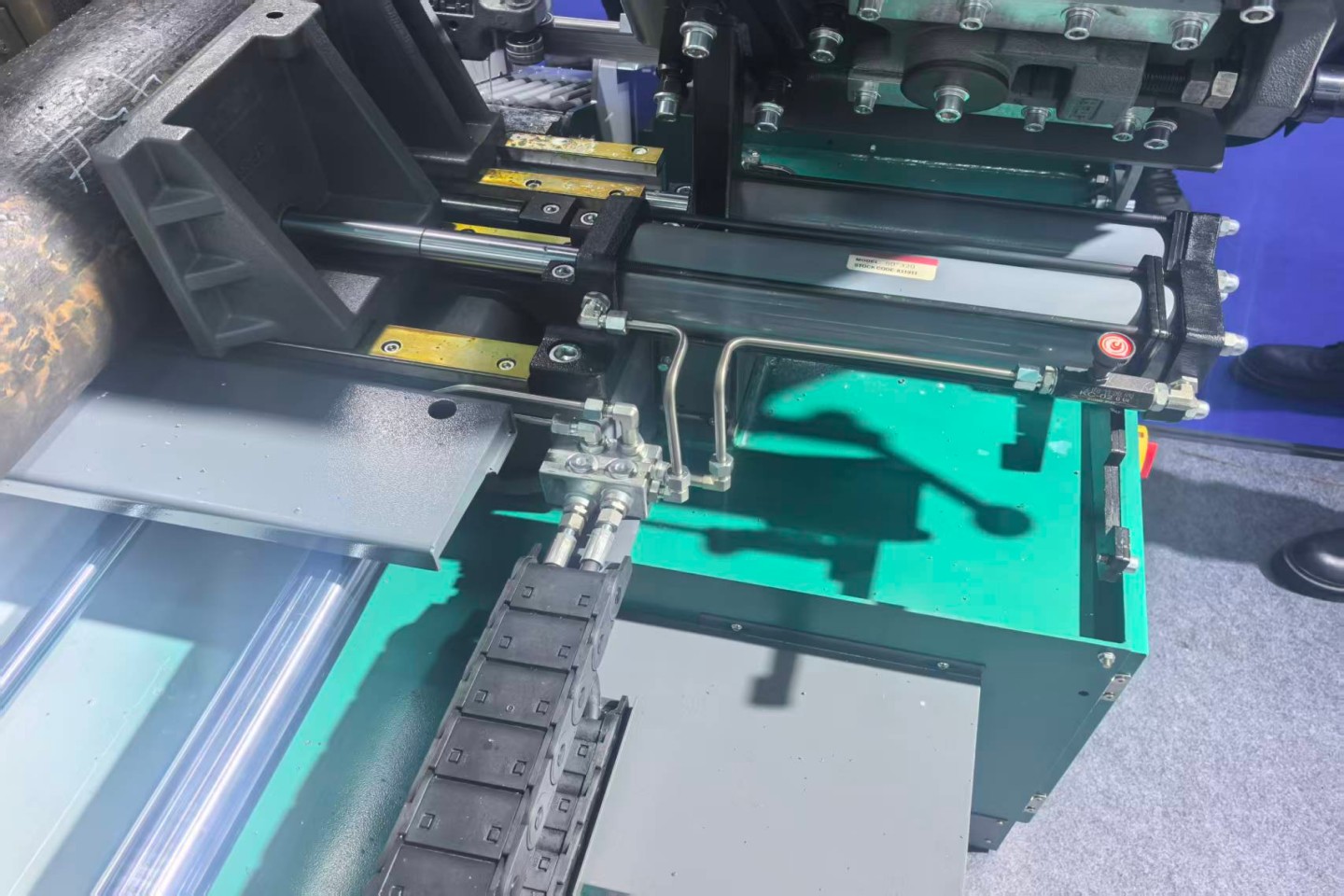

Hydraulic clamping mechanism

Standard configuration includes a hydraulic tensioning device for the saw blade, which intelligently tensions and releases, automatically releasing after machine shutdown to protect the saw blade.

Brand New High-Strength Saw Frame Structure

This machine adopts a brand-new saw frame structure design, manufactured using industrial robot welding technology, and undergoes professional tempering heat treatment to effectively eliminate welding internal stress and significantly improve the structural stability and long-term accuracy of the saw frame.

Magnetic Scale and Protective Cover

A protective cover is added to the magnetic scale to prevent impact. A dustproof and oil-proof brush is also installed to extend the lifespan of the magnetic scale.

Electrical Cabinet

Features a centralized control circuit board design. The cabinet is made of cold-rolled steel plate with a powder-coated surface, providing effective dust and water resistance.

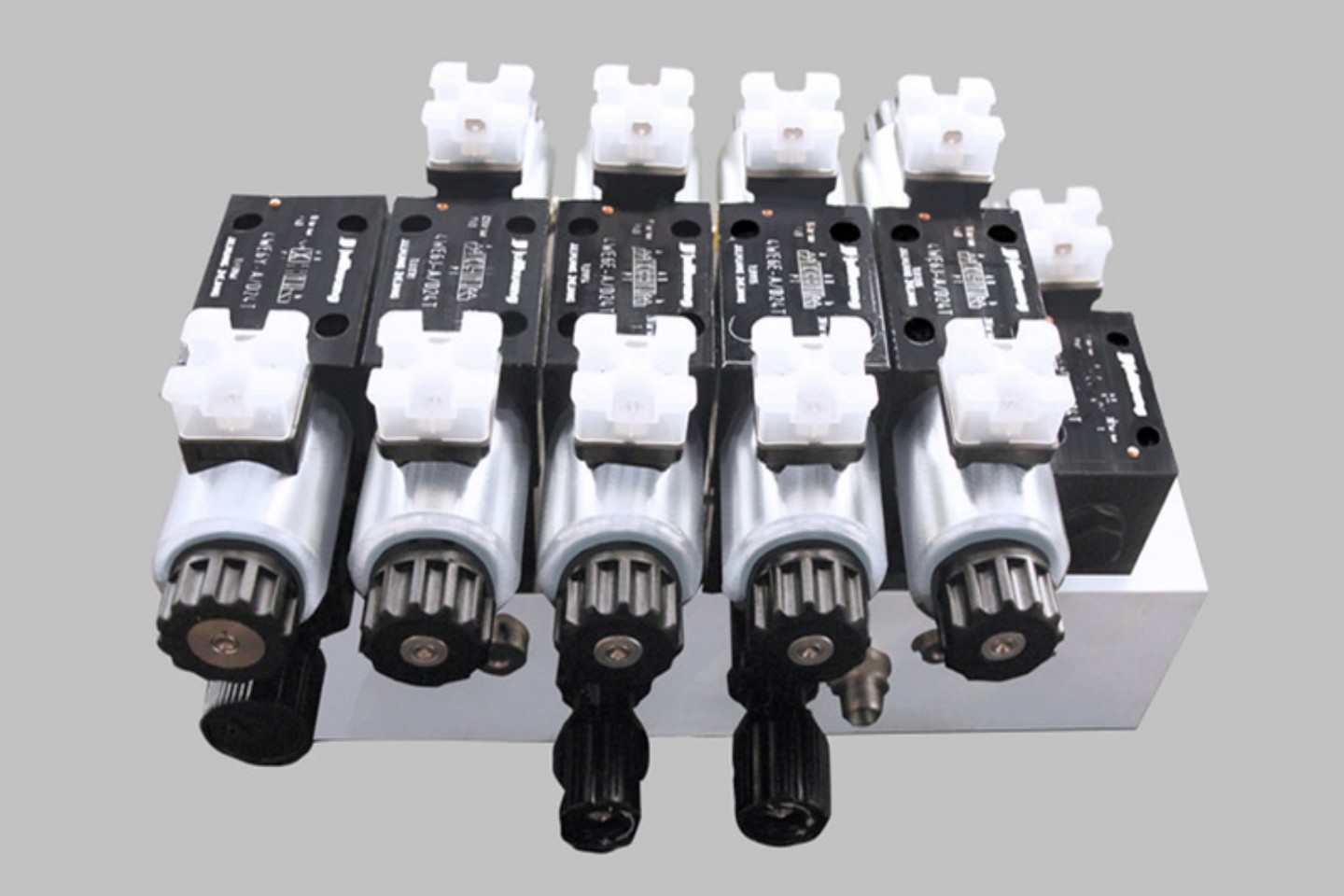

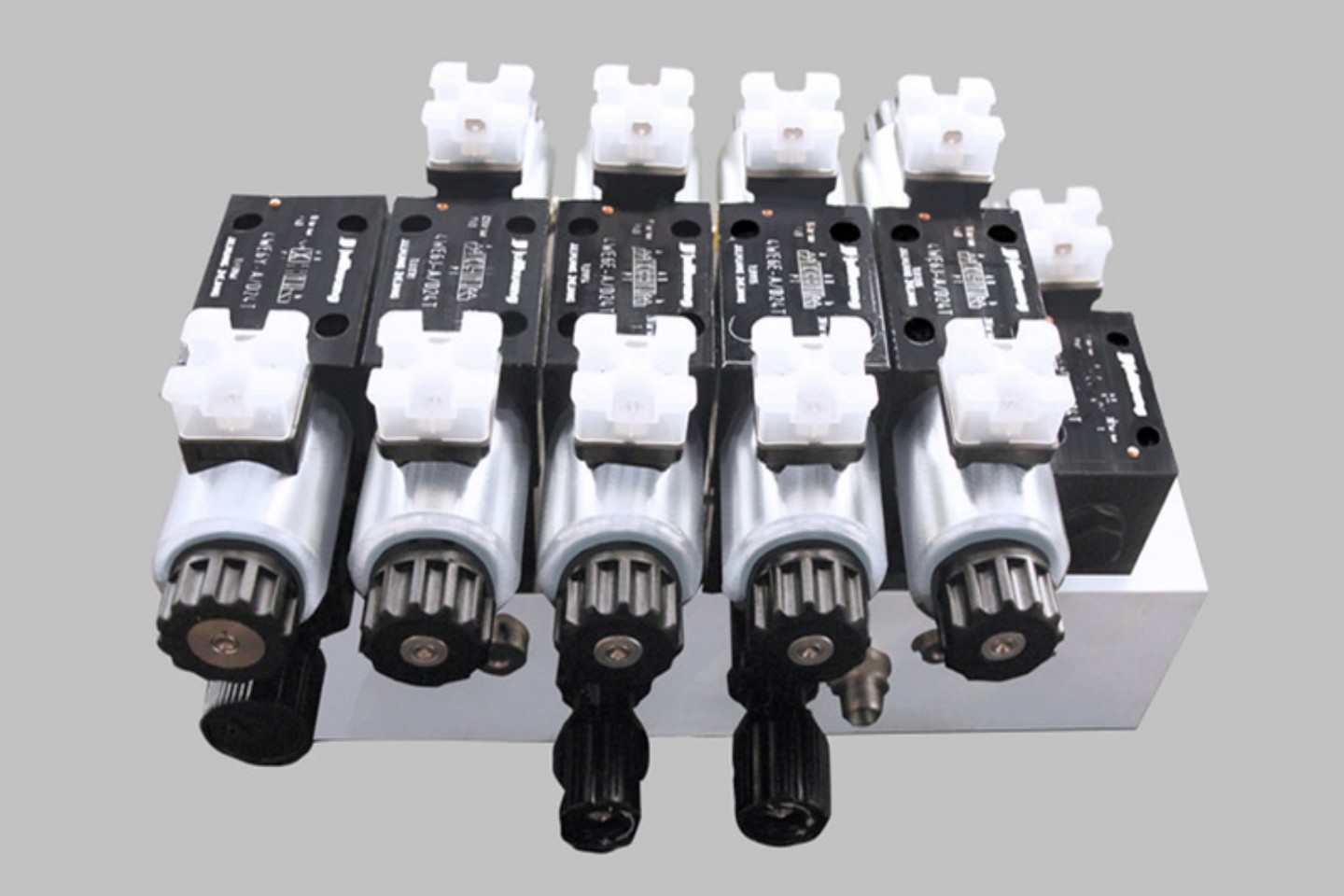

Hydraulic System

The system uses solenoid valve assemblies manufactured by a listed company, ensuring quality and preventing valve jamming. Two sets of stacked pressure-reducing valves are also included. The valve seats are made of aviation-grade aluminum, providing better heat dissipation and facilitating maintenance.

Main technical parameters

Cutting Range:

Bars: 330mm

Profiles: 330×330mm

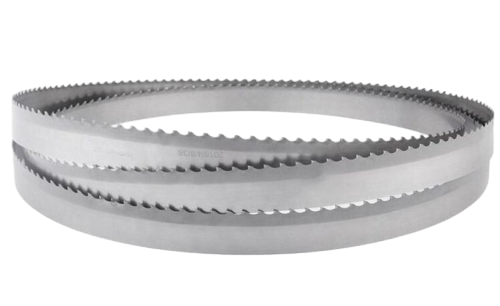

Saw parameters:

Saw band specifications: 4115×34×1.1mm

Saw band speed: 10-80m/min

Power

Main motor: 5kW

Hydraulic motor: 1.1kW

Cooling motor: 90kW

Personalized options

Servo feeding

Bridging structure

Standard Configuration

Schneider Low Voltage Electrical Equipment

Chip Conveyor

Joint Venture Brand Limit Switch

Hydraulic Tensioner

Joint Venture Brand Switches and Buttons

Variable Frequency Speed Control

Intelligent Adaptive Sawing System

Base Adjustment Pads

Other:

Hydraulic oil: 60L

Cutting oil: 90L

Machine dimensions: 2250×2300×1550mm

Machine weight: ≈1700kg; Main drive: Reducer

∅200 solid steel, 3.29-point single-blade cut

45# steel

Total number of sawing cuts: 380+

Sawed area: 12㎡+

Why Choose LJA Machinery

Over 20 years of manufacturing experience

Strict quality control before shipment

Customized solutions available

Exporting to multiple countries worldwide

Technical support and after-sales service provided

FAQ

Q1: What materials can the band saw cut?

A: Carbon steel, stainless steel, aluminum, copper, and alloy steel.

Q2: Does it offer automatic feeding?

A: Yes, semi-automatic and fully automatic models are available.

Q3: Can the machine be customized?

A: Yes, cutting capacity, voltage, and configuration can all be customized.