High Speed Circular Saw Machine display

High-efficiency and precision cutting solution for metal bars, pipes and profiles

∅60 45# Infeed per tooth: 99 microns+

6.6-second single-blade cut Saw area: 40㎡+

-

High-speed cutting, stable and efficient

-

Smooth cutting surface, low burr

-

Accurate length control for batch production

-

Rigid structure, long service life

- Interlocking double-wallet design, high stability

Product Description

-

The high-speed circular saw machine is designed for industrial metal cutting applications that require high efficiency, precision, and stable performance. It is widely used for cutting metal bars, tubes, and profiles in continuous production environments.

-

Compared with conventional cutting methods, this machine significantly improves cutting speed while maintaining excellent cutting accuracy and surface quality, helping manufacturers reduce labor cost and increase production output.

Applicable materials

Carbon steel Solid round bars

Stainless steel Metal pipes / tubes

Aluminum Square & rectangular profiles

Copper Angle steel and special profiles

Alloy steel

Working Principle & Machine Structure

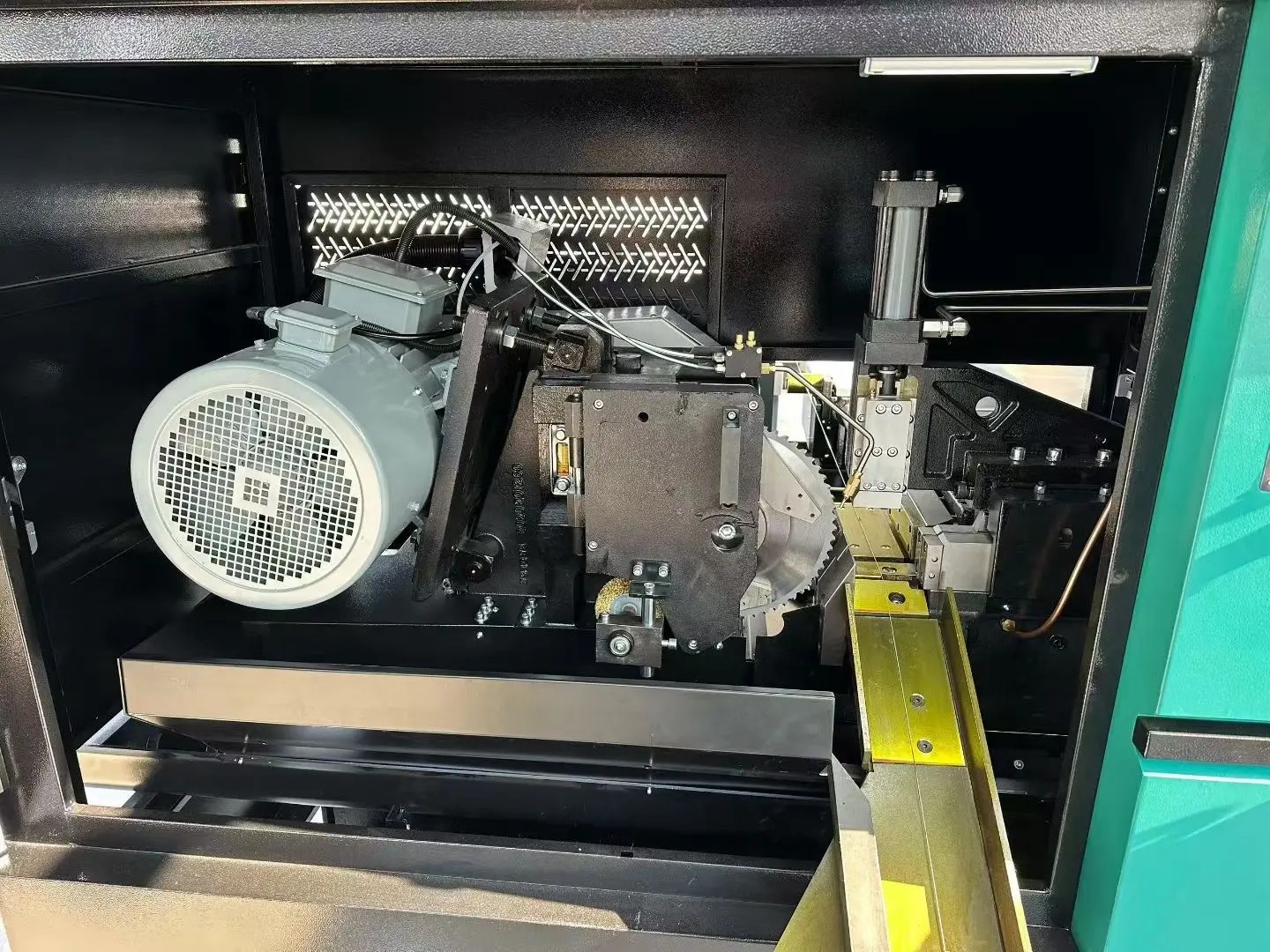

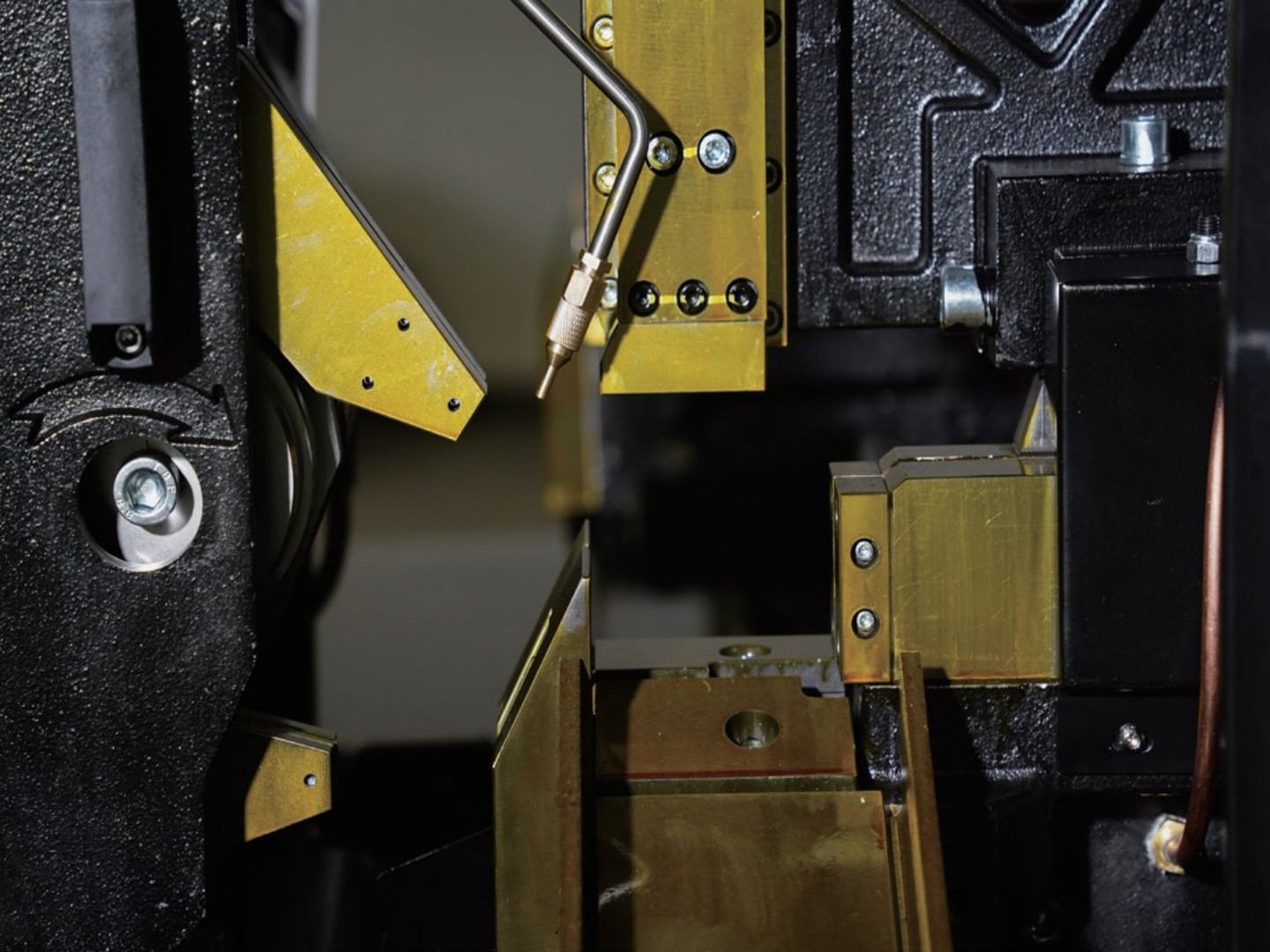

High-Speed Saw Blade System

The saw blade rotates at high speed, ensuring fast cutting efficiency and stable cutting performance.

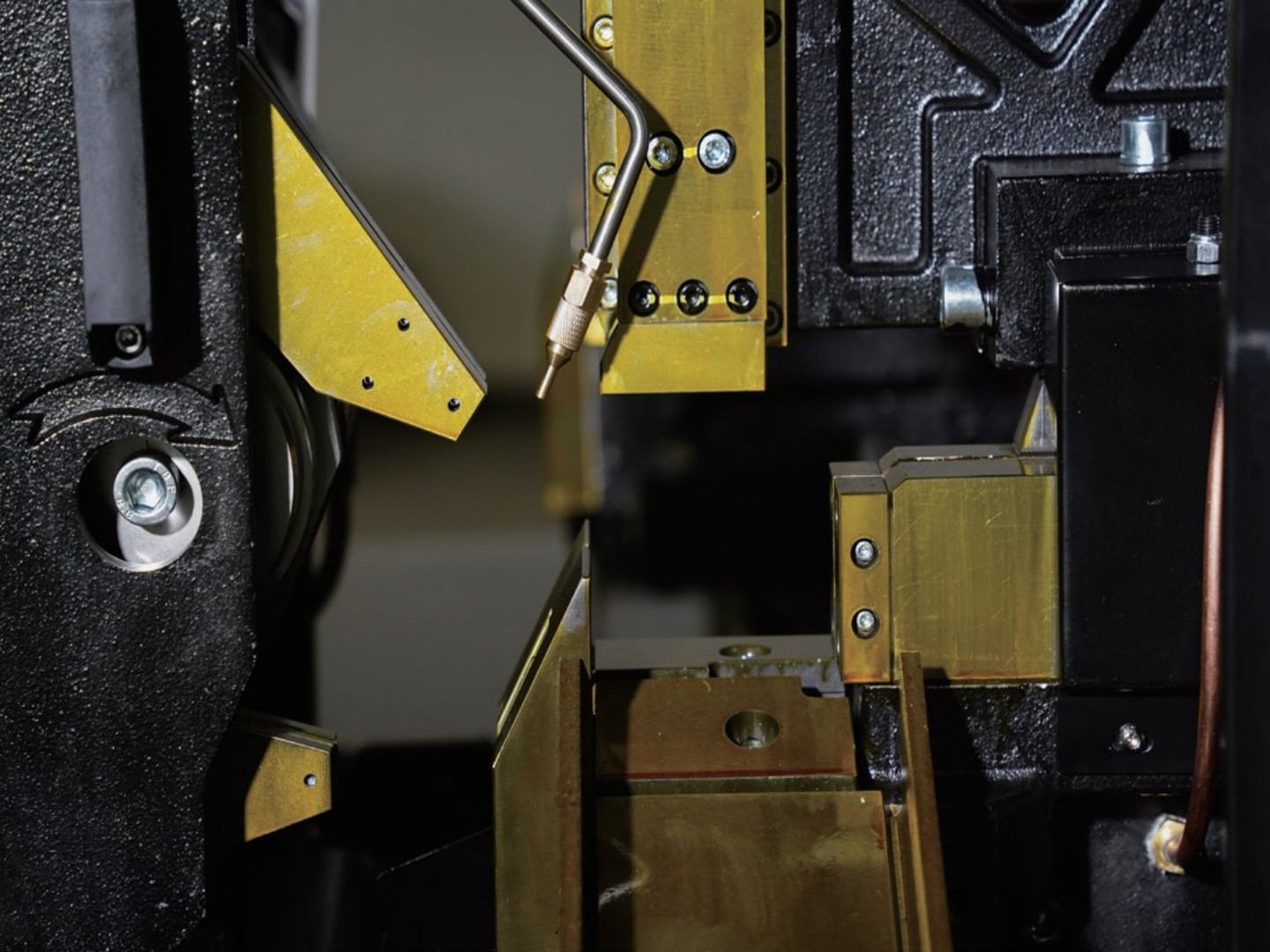

Precision Clamping System

The material is firmly clamped during cutting to prevent displacement and ensure cutting accuracy.

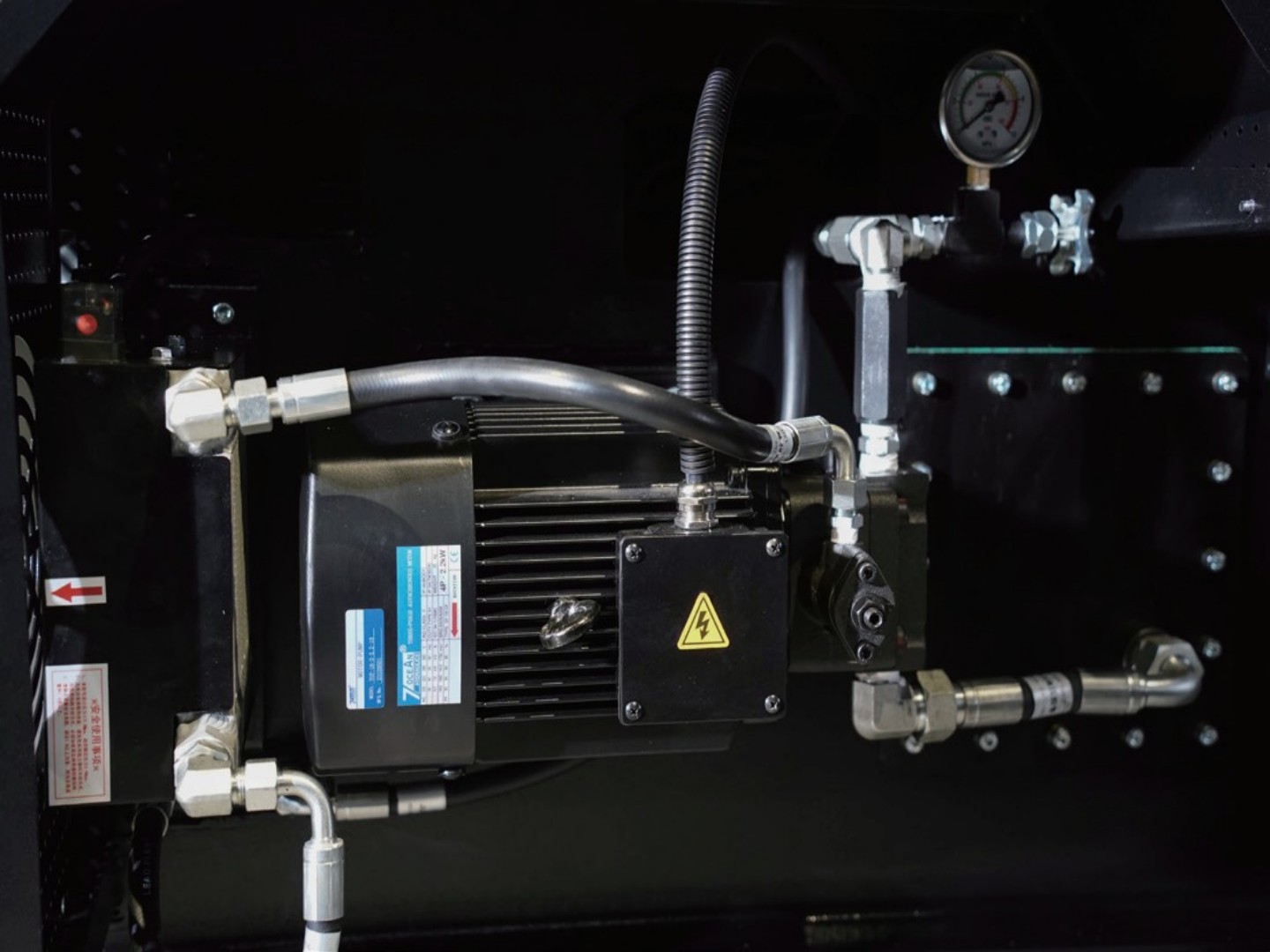

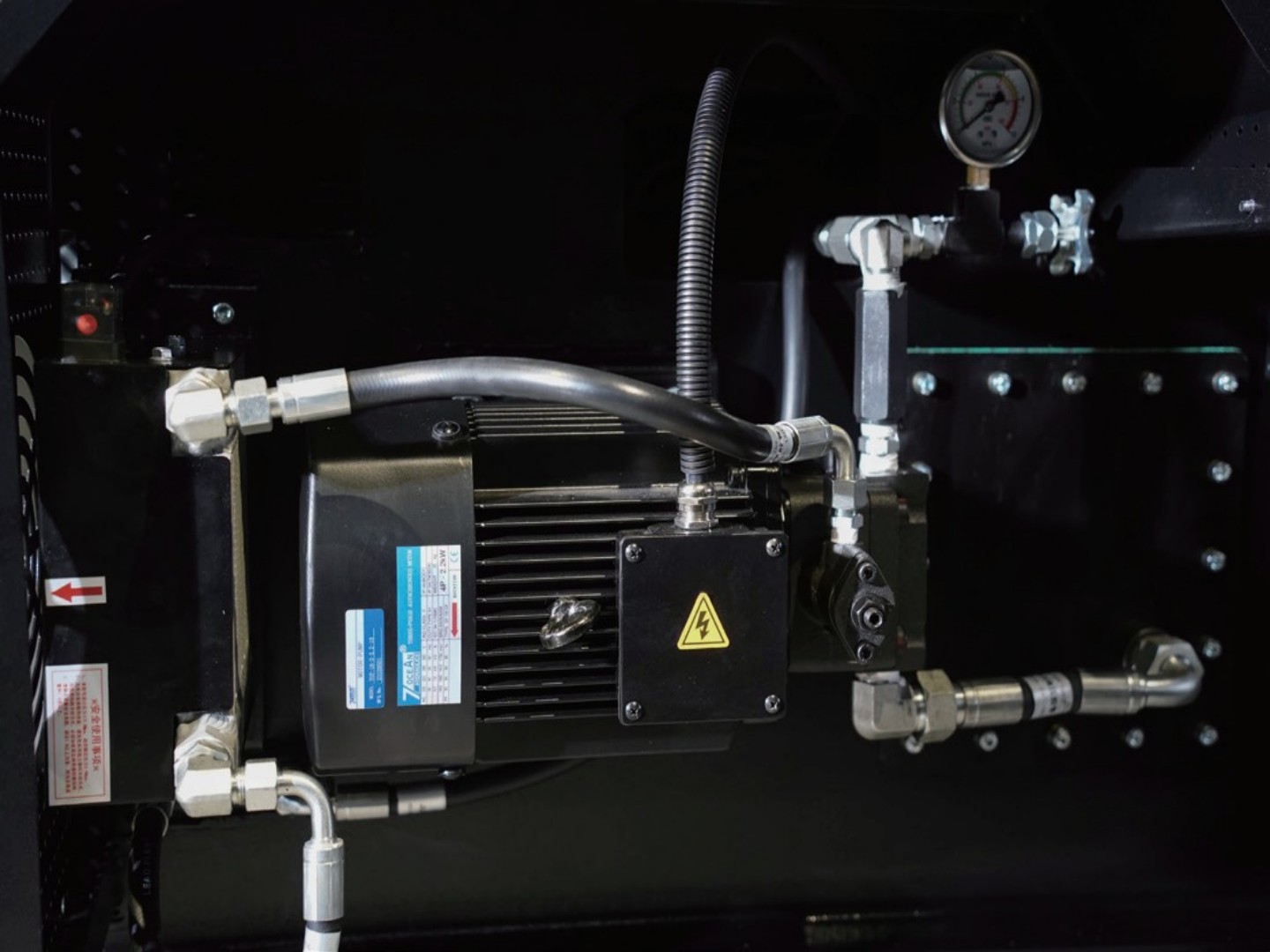

Heavy-Duty Machine Frame

The rigid structure minimizes vibration during high-speed operation, improving cutting stability and blade lifespan.

Automatic Cutting Cycle

Feeding, clamping, cutting, and discharging are completed in a continuous and smooth working cycle.

Key Advantages

-

-

-

High Cutting Efficiency

Short cutting time, suitable for mass production.

-

Excellent Cutting Accuracy

Consistent cutting length with minimal error.

-

Smooth Cutting Surface

Reduces or eliminates secondary processing.

-

Low Noise and Stable Operation

Improves working environment.

-

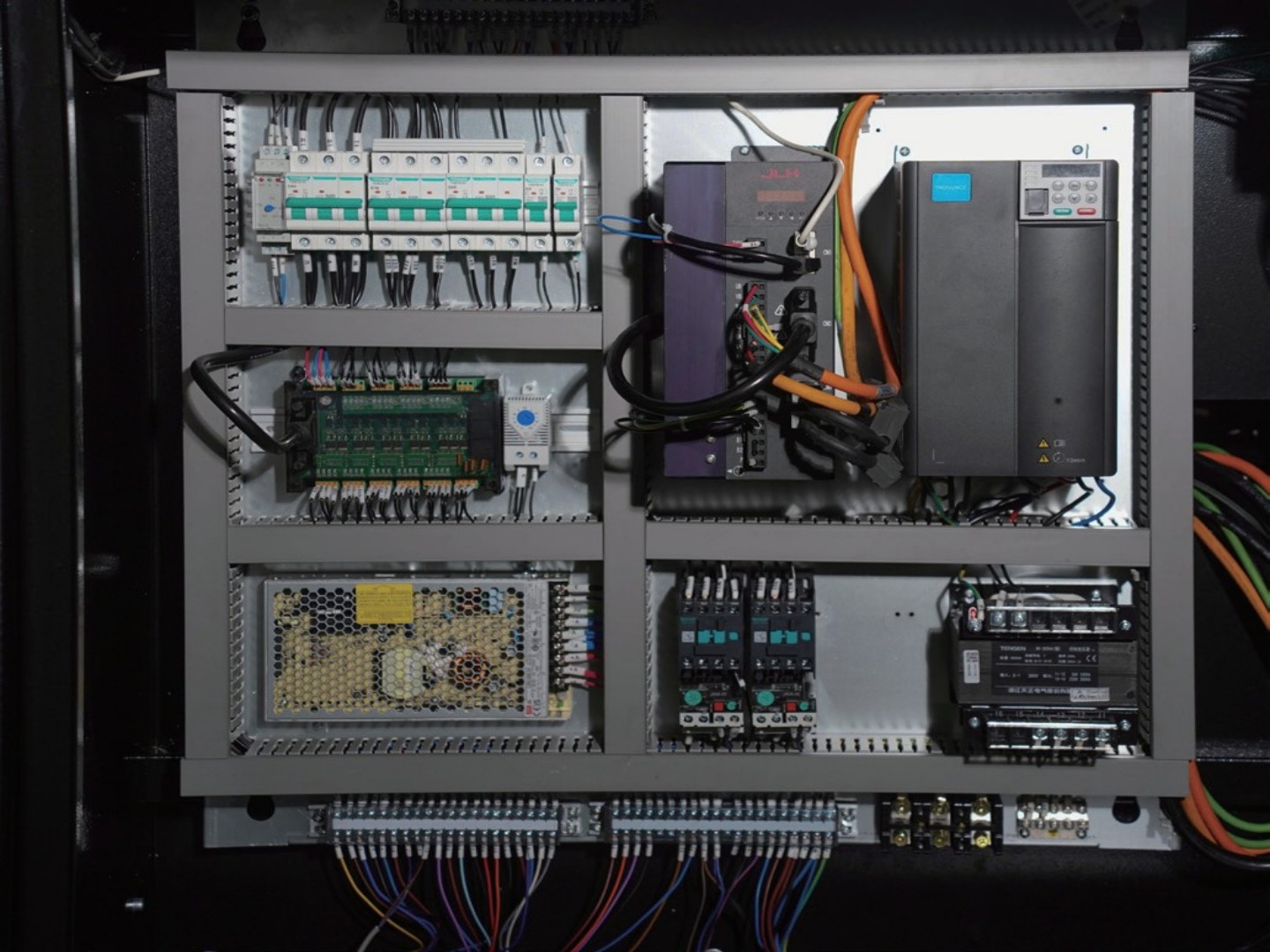

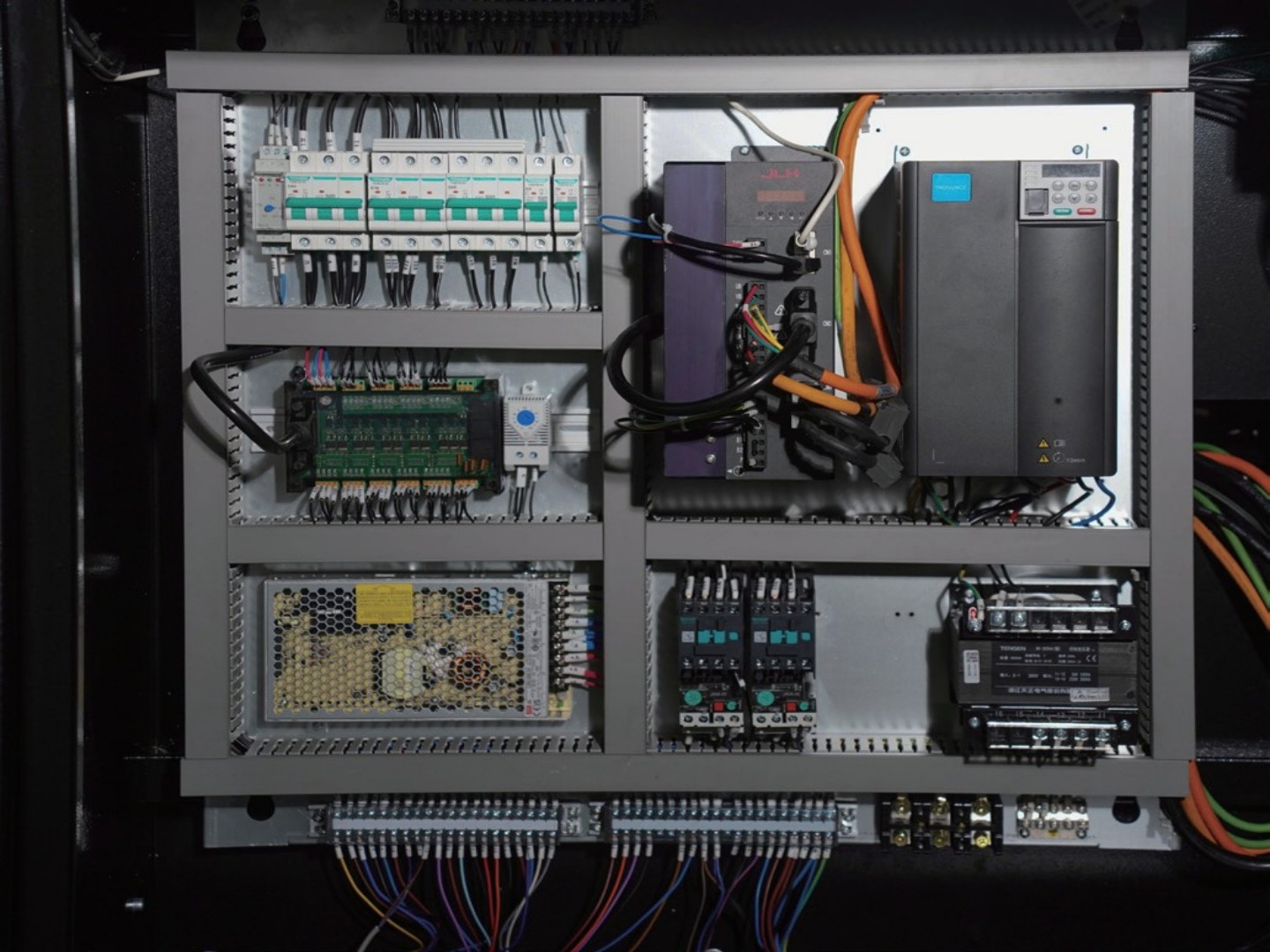

Easy Operation & Maintenance

Simple control system, low maintenance cost.

-

Long Blade Service Life

Stable cutting reduces blade wear.

Standard Configuration & Optional Configuration

Application scenarios

Metal fabrication workshops

Furniture & hardware manufacturing

Automotive parts processing

Construction material production

Machinery manufacturing plants

FAQ

Q1: What materials can this high-speed circular saw machine cut?

A: It is suitable for carbon steel, stainless steel, aluminum, copper, and alloy steel.

Q2: Is the cutting length adjustable?

A: Yes, the cutting length can be adjusted according to production requirements.

Q3: Can the machine be customized?

A: Yes, we provide customization based on cutting capacity, automation level, and electrical standards.

Q4: Do you provide technical support?

A: We provide operation manuals, technical guidance, and online support.