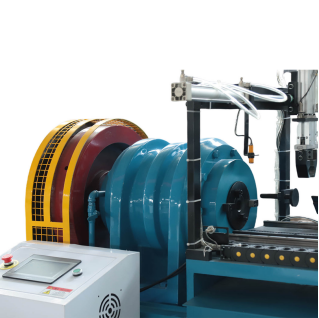

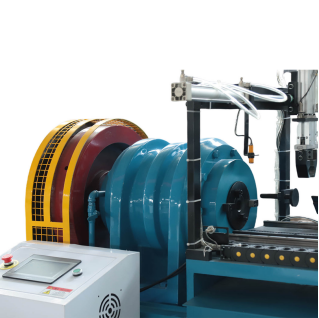

Features of a fully automatic cone tube machine

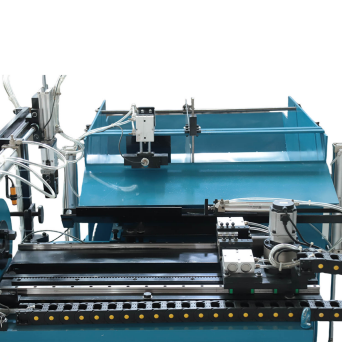

- LJA Machinery Fully Automatic Tube Tapering Machine (Customizable)

- Capable of tapering various metal tubes and bars.

- Fully automatic tapered tube processing machines are widely used in furniture manufacturing, automotive exhaust systems, lamp holders, fitness equipment, ventilation ducts, and mechanical parts industries.

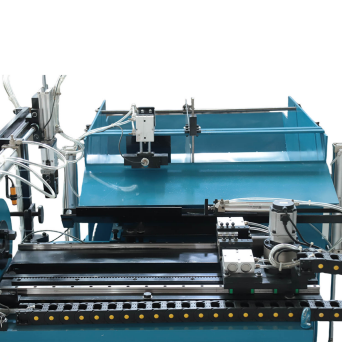

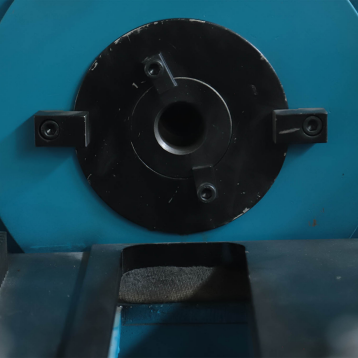

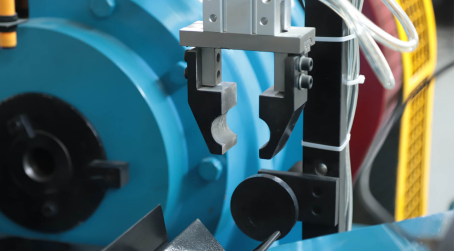

- This equipment employs a mechatronic control system, using servo motors and hydraulic drives to precisely control tube feeding, clamping, rotation, and forming actions.

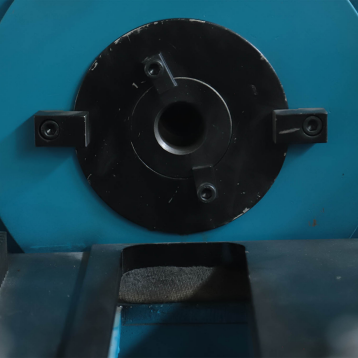

- The system supports multi-segment program settings, enabling the processing of tube ends with different taper angles, lengths, and shapes, achieving high-precision repeatable processing.

- The entire machine utilizes a thickened steel frame structure and a high-rigidity spindle to ensure stable operation.

- Processing accuracy can reach ±0.1mm, with production efficiency increased by more than 50% compared to traditional equipment.

- It supports quick mold changes and multi-size compatibility, and can be customized to different specifications and special end face structures according to customer needs.

Intelligent pipe end forming solution

- The fully automatic tube tapering machine is an intelligent device specifically designed for forming and processing metal tube ends.

- Through a fully automated control system, it automates the entire process from loading to positioning, forming, and unloading, requiring only a single button press by the operator.

- It produces smooth tapers with high dimensional consistency, significantly improving production efficiency and reducing labor costs.

- It is widely used in industries such as building decoration, furniture tubing, automotive parts, air conditioning ducts, lighting poles, and fitness equipment.

- It supports various pipe diameters, different taper angles, and customized molds, truly achieving a highly efficient, precise, and intelligent tube end processing solution.

Application Samples

- 🚗 Car exhaust pipes / muffler tapered sections

- 💡 Lighting poles / light post tapered sections

- 🪑 Furniture decorative sections / chair leg sections

- 🏗️ Architectural decorative round sections / railing sections

- 🏋️ Fitness equipment handrails / frame sections

- 🌬️ Ventilation duct tapered sections