Duct Production Line 3

Automatic HVAC Rectangular Duct Manufacturing Line

High-Efficiency Integrated Solution for HVAC Duct Fabrication

Duct Production Line 3 is a highly integrated automatic duct manufacturing system designed for efficient production of rectangular HVAC ducts.

It combines decoiling, leveling, beading, cutting and flange forming into one continuous production line, significantly improving productivity while reducing labor cost.

High efficiency solution for rectangular duct fabrication

-

Fully automatic production

-

Integrated coil to duct system

-

Stable performance & high precision

Get Quotation / Contact Us

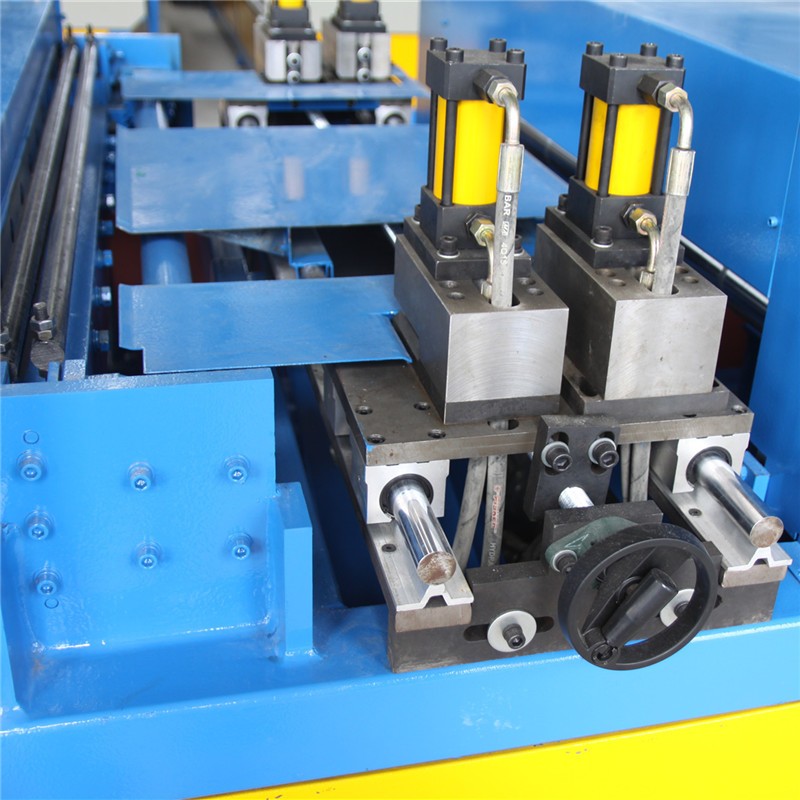

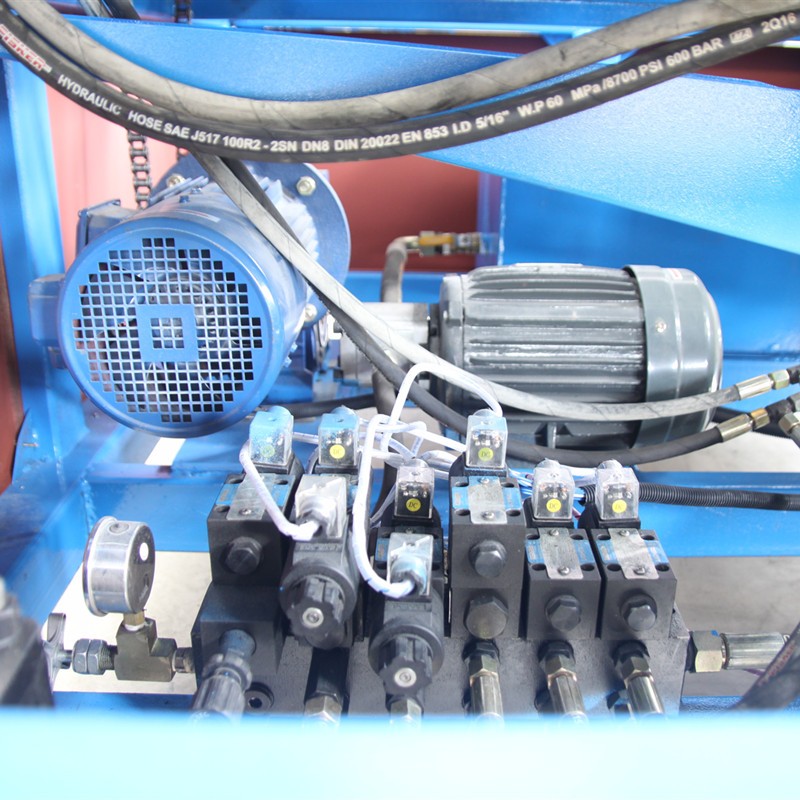

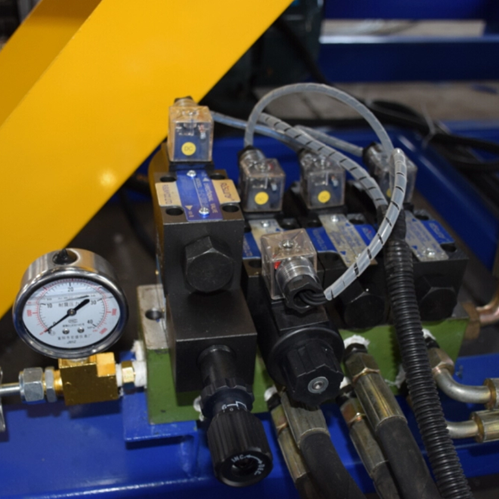

Main components of the machine

Key Advantages

Duct Production Line 3 is designed for medium to large-scale duct production, offering stable performance, high forming accuracy and consistent product quality.

With PLC intelligent control, the whole line runs automatically from metal coil feeding to finished duct sheet output.

High Production Efficiency

Continuous automatic production significantly increases output and reduces production time.

Stable & Accurate Forming

Precision leveling and forming systems guarantee uniform duct size and high surface quality.

Easy Operation

PLC control system with touch screen interface allows easy operation and quick setup.

Low Labor Cost

Only 1–2 operators are required to run the entire production line.

Reliable Structure

Heavy-duty machine frame ensures long service life and stable operation.

Applications

Duct Production Line 3 is widely used in:

-

HVAC duct manufacturing

-

Commercial building ventilation systems

-

Industrial ventilation projects

-

Tunnel and metro ventilation

-

Hospital and clean room air systems

Why choose us?

-

High level of automation

-

Stable and reliable performance

-

Flexible configuration options

-

Suitable for mass production

-

Professional technical support and after-sales service

FAQ

Q1: What production capacity is this line suitable for?

A: It is ideal for medium to large duct manufacturing factories with continuous production needs.

Q2: Can the machine be customized?

A: Yes, customization is available based on material thickness, width and flange type.

Q3: How many operators are required?

A: Usually only 1–2 operators are needed.

Q4: Can it process stainless steel?

A: Yes, stainless steel can be processed within the specified thickness range.