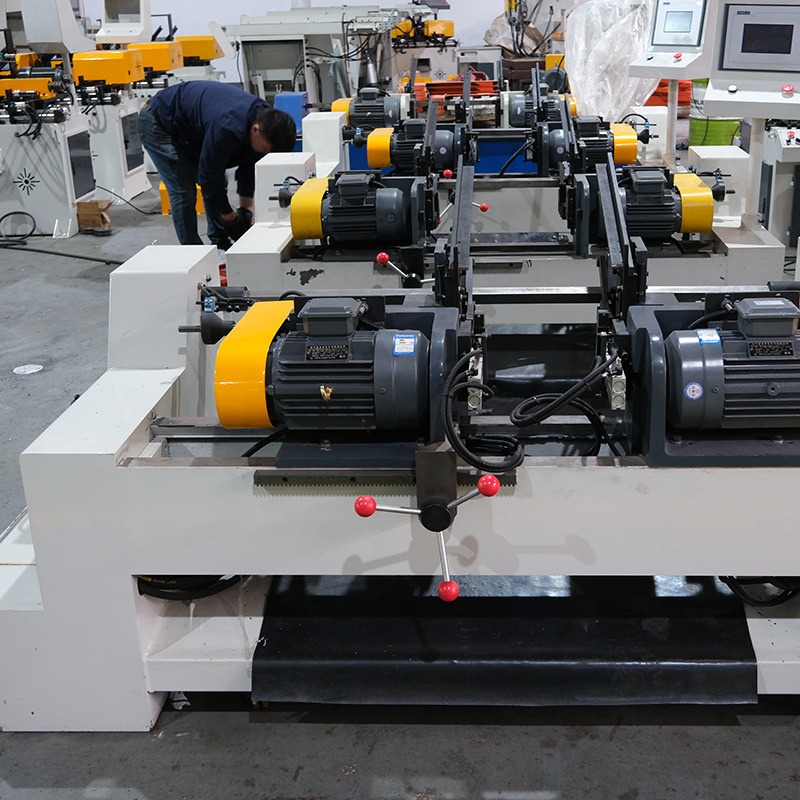

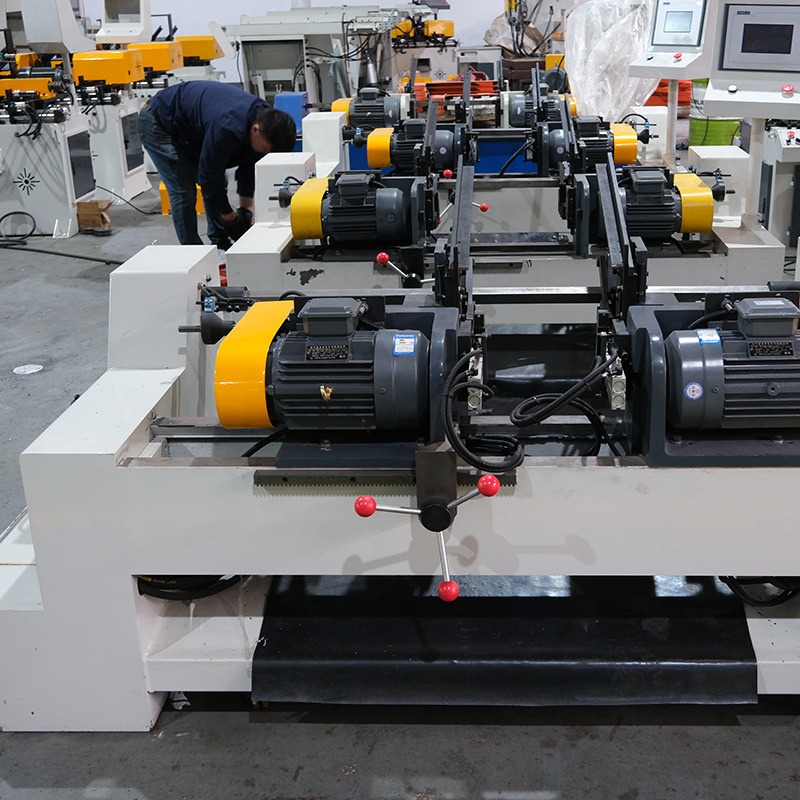

Advantages of LJA Double-Head Chamfering Machine

- Manual feeding, automatic clamping, automatic tool feed and retraction, high speed.

-

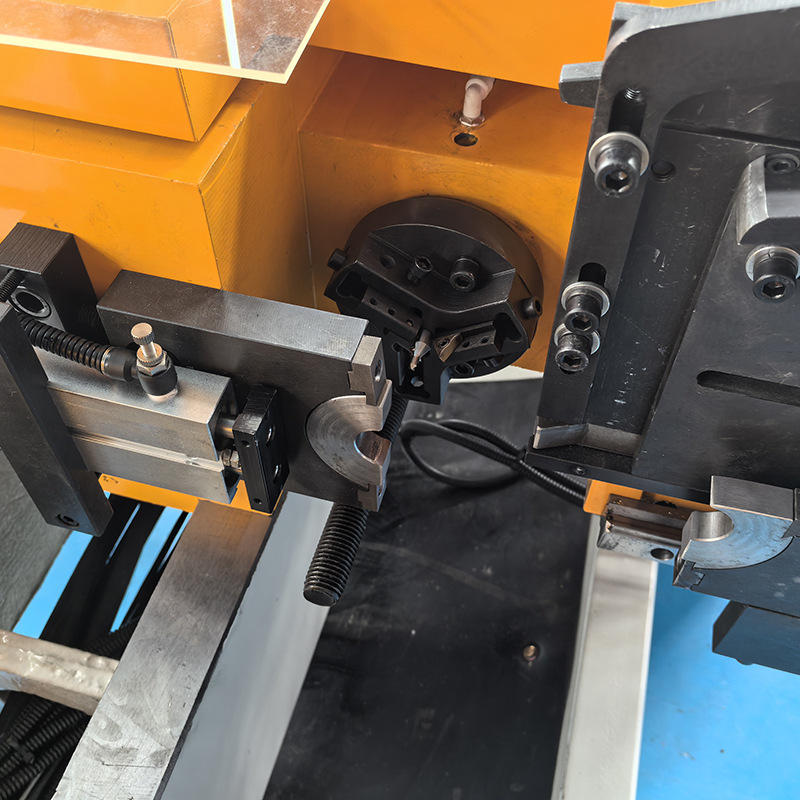

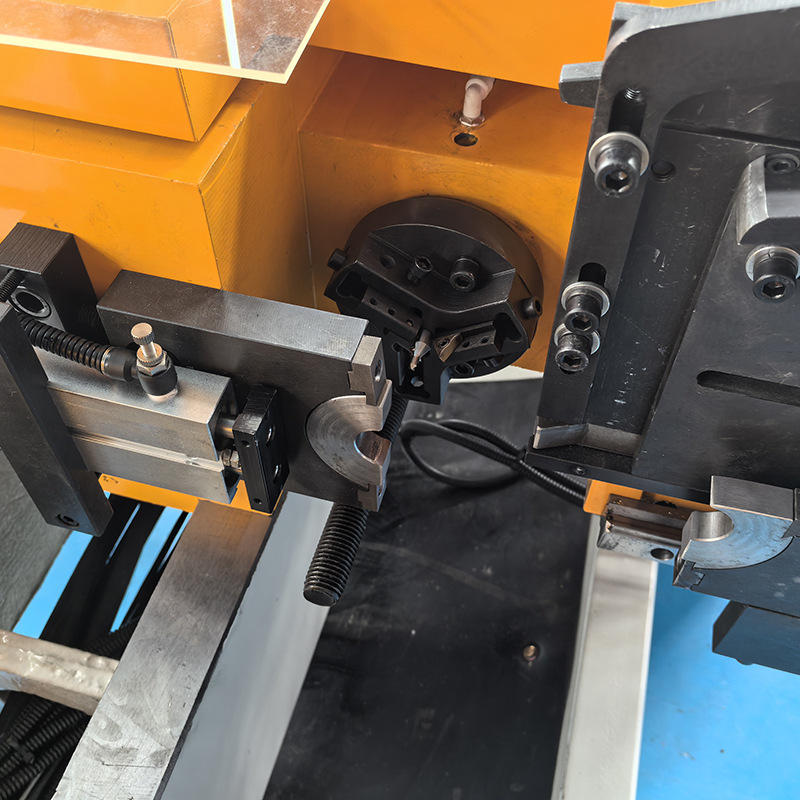

The ingeniously designed clamping die and cutter head ensure accurate and consistent centerline between the workpiece and the cutter head, allowing for uniform machining of the outer and inner corners and end faces of pipes in a single pass.

-

For workpieces of different sizes, only simple changes and adjustments to the cutter head and clamping die are required.

-

Multiple speeds can be switched using pulley variations to adapt to various metal materials and achieve maximum tool life.

-

Two-stage feed speed saves time, and the slower speed is easily adjustable for perfect machining.

- The clamping die and cutter head are exquisitely designed to ensure that thecenter line of the machining object and cutter head is accurate and unchanged,

- By changing the pulleys, multiple speeds can be achieved to accommodate various metal materials, thus maximizing tool life. Cuttable materials include: steel, stainless steel, cast iron, copper, plastics, and multi-layered pipes.

The Superior Value of Dual-Head Synchronous Machining Technology

1. High-Efficiency Dual-Head Synchronous Operation

Dual spindles are controlled synchronously or independently, completing machining at both ends in a single setup, increasing efficiency by over 100%.

Eliminates time and manpower spent on workpiece flipping and secondary positioning, enabling continuous assembly line operation.

2. Precision Machining and Excellent Consistency

Servo motor drive ensures precise tool feed, guaranteeing perfectly consistent chamfer dimensions at both ends.

High-precision fixtures and guiding systems eliminate workpiece vibration, ensuring smooth and flat bevels.

Especially suitable for precision workpieces with strict requirements for parallelism and symmetry at both ends.

3. Strong Material and Process Adaptability

Standard configuration includes high-performance carbide inserts; CBN tools are optional, easily handling materials such as carbon steel, stainless steel, alloy steel, copper, and aluminum.

Can machine various forms of bevels, including V-grooves, composite bevels, and rounded chamfers; angles are adjustable.

Suitable for round tubes, square tubes, round bars, and certain profiles with specific cross-sections.

4. Intelligent Control and Stable Durability

User-friendly CNC interface with preset common process parameters for simple and quick operation.

Fully enclosed protection and automatic chip removal system maintain a clean and safe working environment.

Heavy-duty bed structure; core components undergo heat treatment and precision grinding to ensure long-term machining stability.