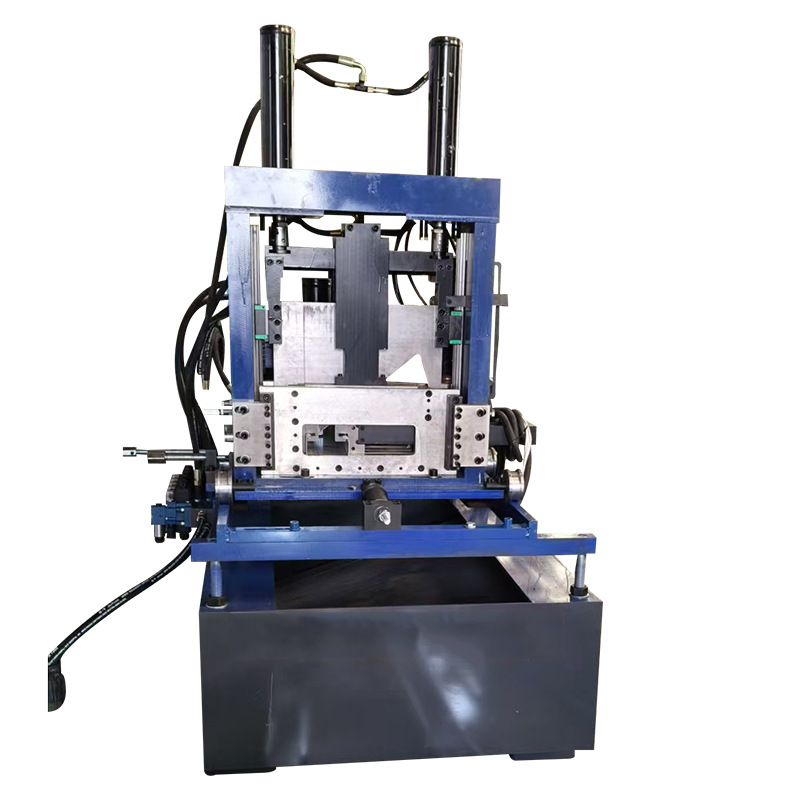

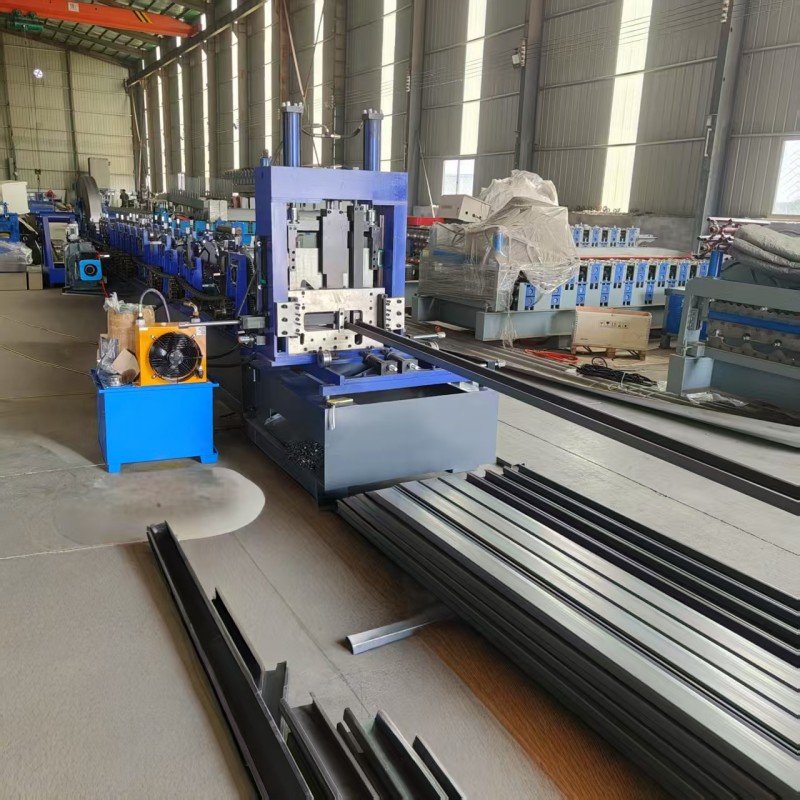

C/Z Purlin Forming Machine

Purlin Forming Machine – High-Precision C/Z Purlin Cold Bending Forming Solution

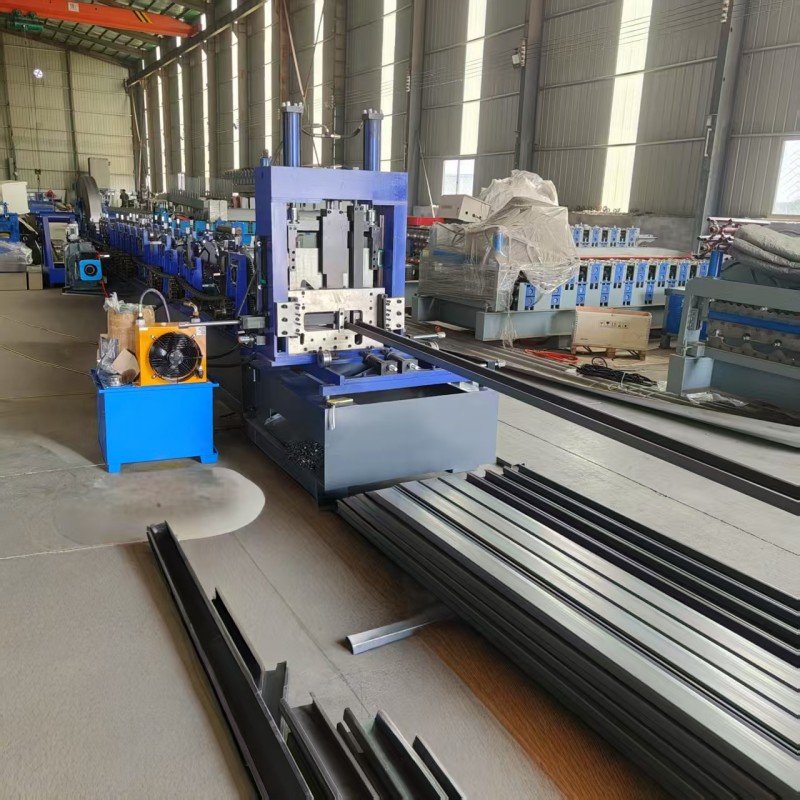

This C-type/Z-type continuous forming equipment is specifically designed for steel structure buildings. It is suitable for various metal materials such as galvanized steel sheets and cold-rolled steel sheets, and features stable operation, high forming precision, and supports customized production.

Before leaving the factory, the entire production line is tested to ensure stable processing and delivery.

Why Choose This Machine

✅ High-precision continuous cold bending forming

Multi-pass roller forming ensures high dimensional consistency.

Excellent straightness of the purlins, meeting steel structure installation requirements.

✅ Supports production of multiple C/Z purlin specifications

Covering various height and width specifications

Optional manual/semi-automatic/fully automatic specification adjustment

✅ Stable and durable, suitable for long-term operation

High-strength frame structure

Key components are made of high-quality alloy steel

✅ High degree of automation

PLC control system

Automatic fixed-length cutting reduces manual intervention.

LJA PRF-CZ300 Purlin Production Line Components:

1) Decoiler:

Type: Mechanical or hydraulic uncoiler

Load Capacity: 6 tons

Roll Inner Diameter: 480-580 mm

Expansion Method: Hydraulic expansion

Method: Electric active uncoiling

2) CZ Type Roll Forming Machine:

Flattening Station: 7 solid shaft rollers plus additional clamping rollers for flattening steel coils

Roller Material: High-grade wear-resistant material, heat-treated, polished, and galvanized

Purlin Machine Main Drive: Hydraulic motor or servo motor drive

Main Shaft Material: 40Cr, heat-treated, polished, and galvanized

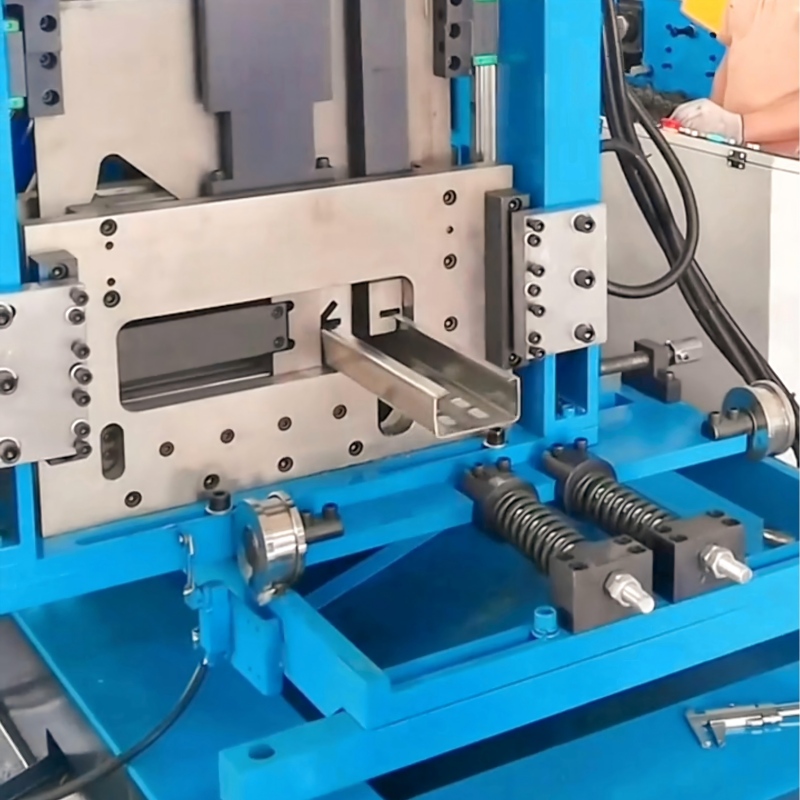

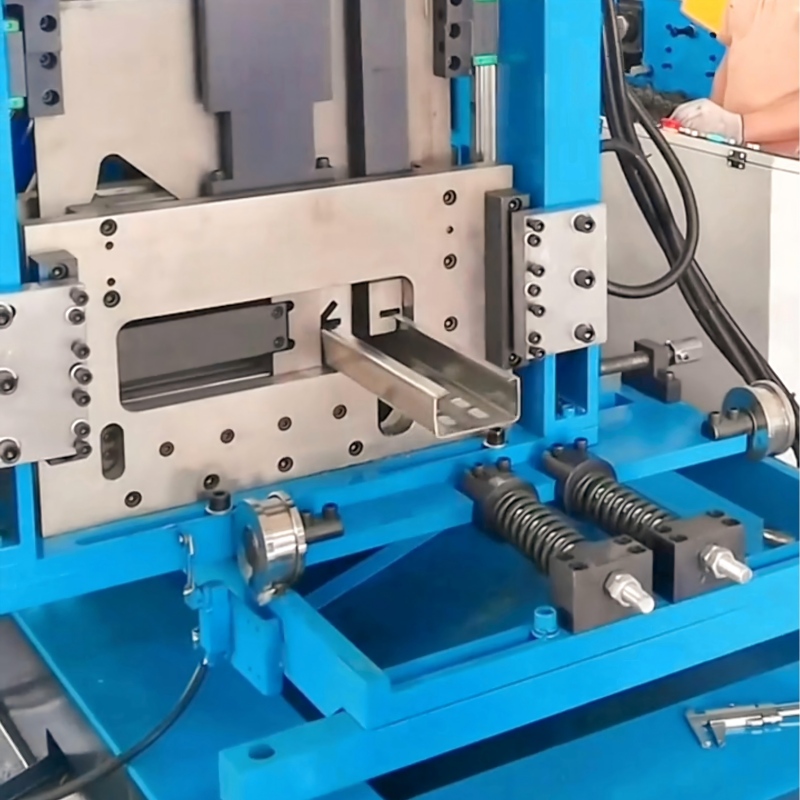

3) Hydraulic Punching and Universal Cutting System:

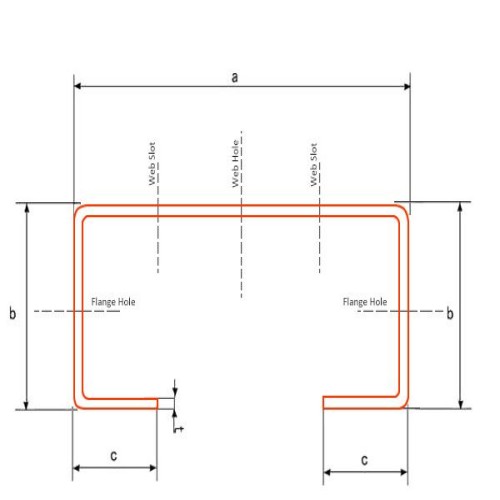

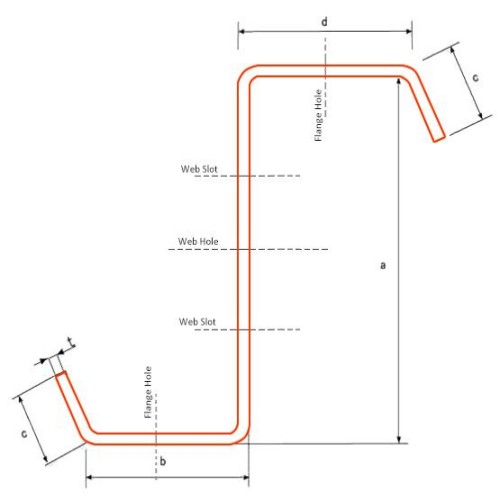

Punching Units: 3 sets + 2 sets

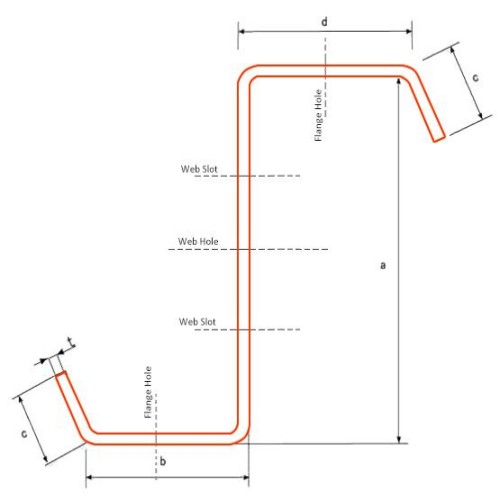

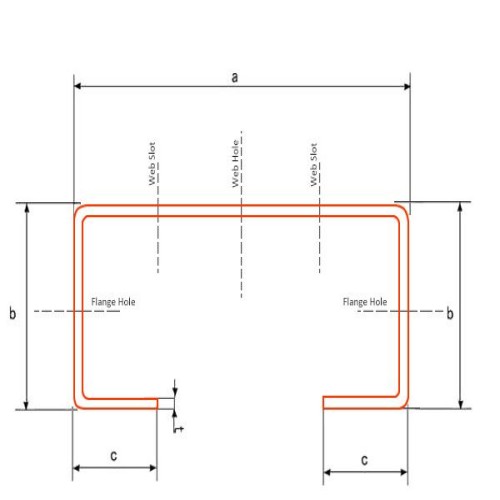

Hole Positions: Web side, flange side

Hole Types: Round hole, slotted hole

Universal Cutting Blade: One cutting blade suitable for all C-type and Z-type purlin sizes

Machine Control: Cutting length, number of pieces, and punching are all automatically controlled by PLC.

Product drawing reference

Q: Do you have CE document and other documents for customs clearance?

A: Yes, we have CE, Provide you with a one-stop service. At first we will show you and and after shipment we will give you CE/Packing list/Commercial Invoice/ Sales contract for customs clearance.

Q: If we are interested in your machine, how do we choose?

1. What main job you do with the machine?

2. What is your request? diameter__mm, thickness__mm, length__mm?

3. What material you want to process, stainless steel, carbon steel?

Q: How about warranty?

A: 2 years quality guaranty, the machine with main parts(excluding the consumables) shall be changed free of charge(some parts will be maintained) when if any problem during the warranty period.

Q: Do you have after sales support?

A: Yes, we are happy to give advice and we also have skilled technicians available across the world, We need your machines running in order to keep your business running.

Q: Can you customize?

A: Yes, non-standard machines can be customized according to your products