Core advantages

Full Servo Control System: Feeding, rotation, and bending are all independently driven by servo motors, ensuring high positioning accuracy and excellent repeatability, suitable for stable batch production.

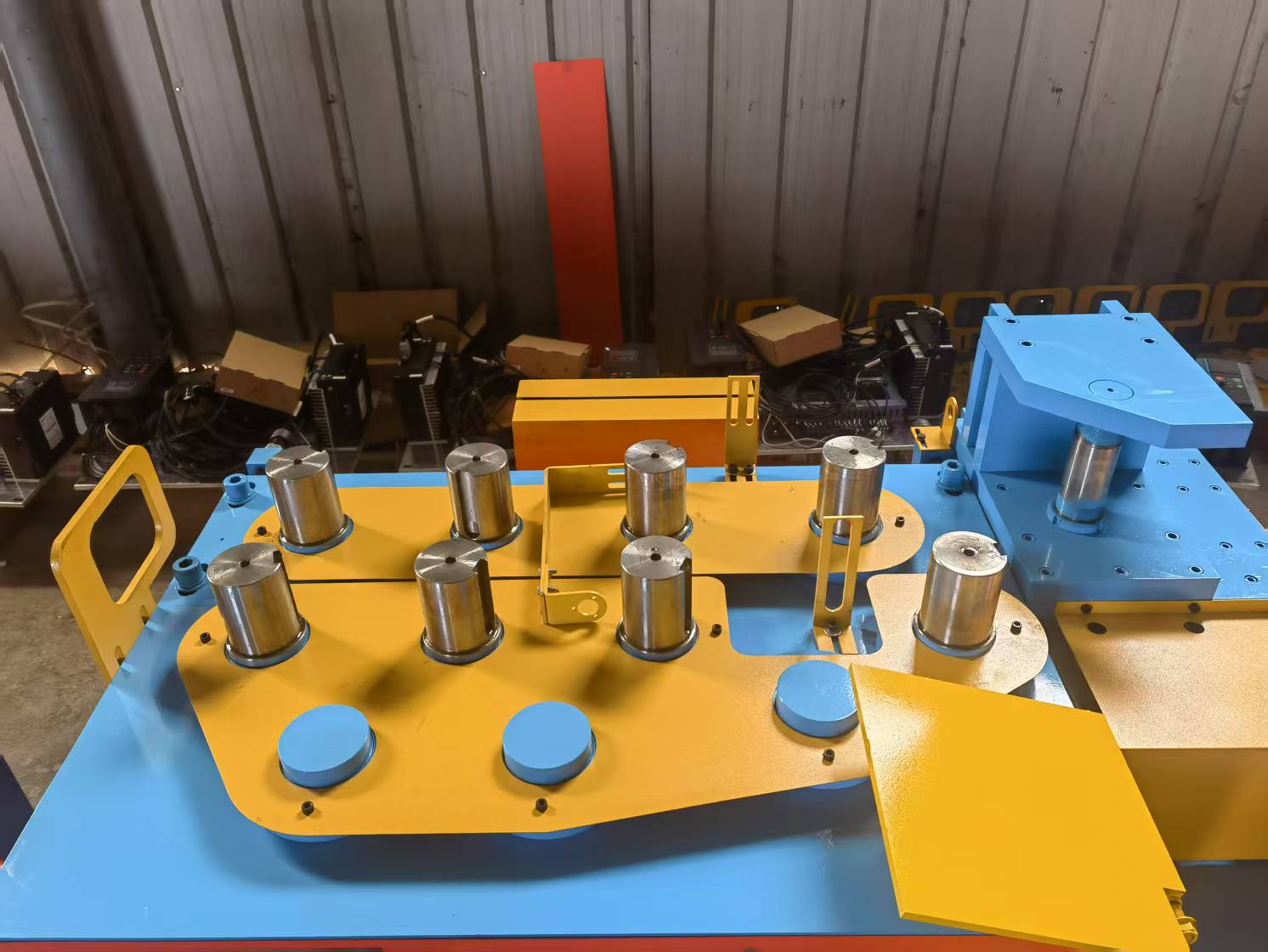

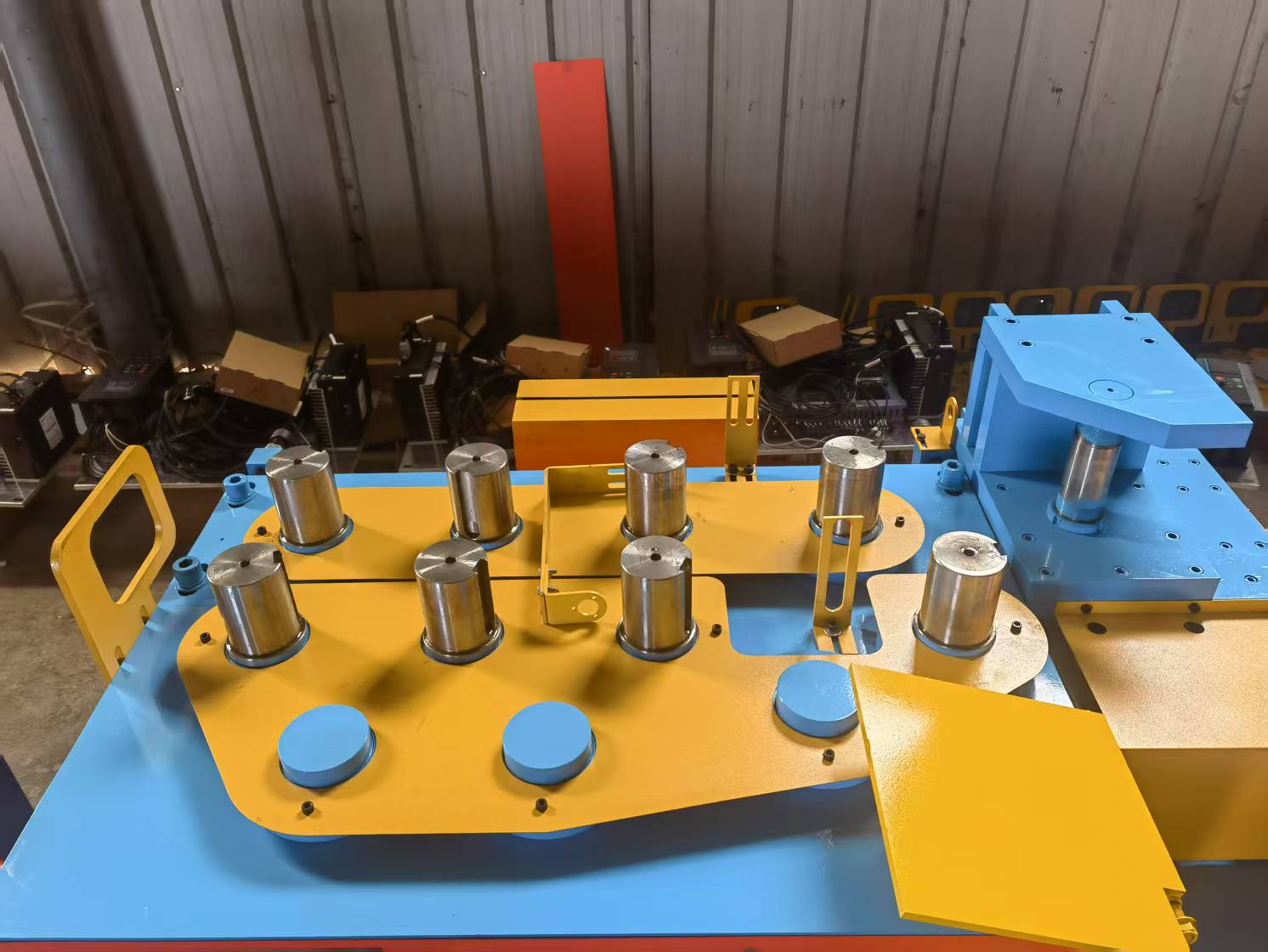

9-Roll Continuous Bending Structure: Multi-roll progressive forming effectively disperses stress, significantly reducing pipe deformation rate and improving the appearance and inner wall quality of the finished product.

Supports Complex Spatial Bending: Enables continuous bending of multiple segments, angles, and radii, meeting the processing needs of complex pipelines and irregularly shaped pipe fittings.

High Efficiency and Low Maintenance: Compared to traditional hydraulic pipe bending machines, it consumes less energy, is easier to maintain, and offers higher long-term operational stability.

Product Description

Top bending roller Large diameter shaft Servo motor

Only adjust the top bending roller can get round Multi-roller transmission is not easy to slide High precision, stable pipe bending

Multifunctional CNC Touch Screen control cabinet Detection device

Multiple operation modes, easy to use High stability and precise control Material detection sensors and counting wheels

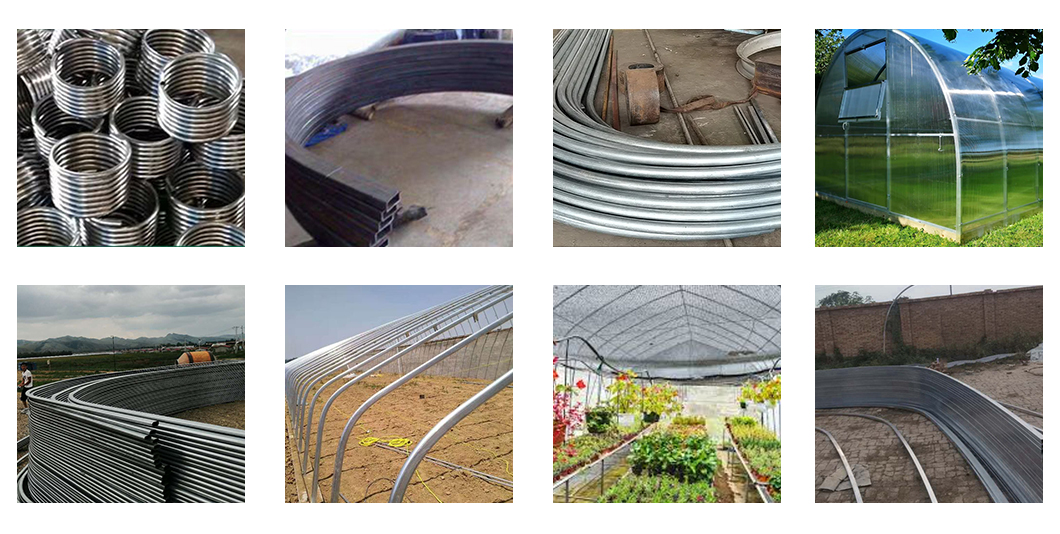

Application scenarios