Equipment Structure and Operation

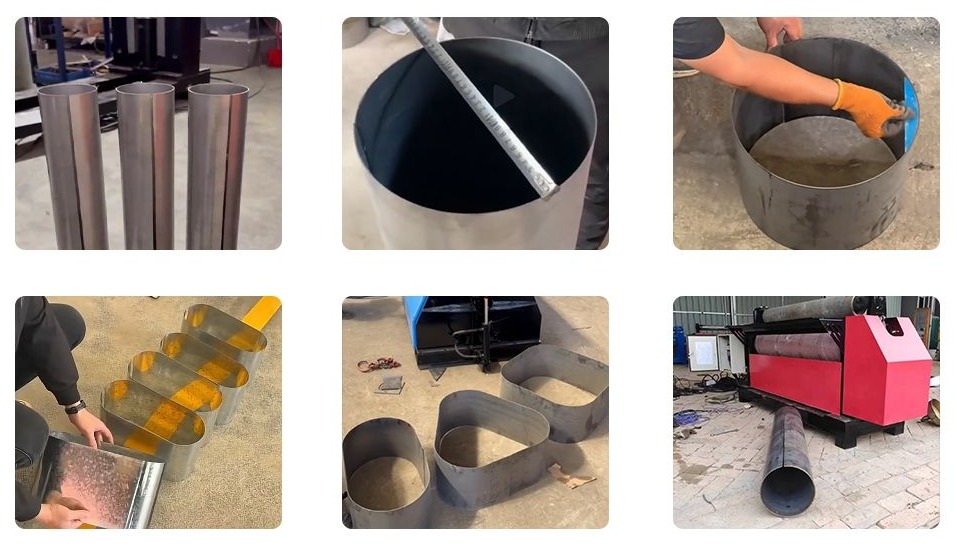

The W12 series adopts a four-roller layout, including an upper roll, a lower roll, and two side rolls.

The lower roll is responsible for clamping and conveying the sheet metal, the upper roll completes the rolling action, and the side rolls are used for pre-bending and forming the ends of the sheet metal. The movement of each roll is driven by a hydraulic system and synchronized with a CNC system, allowing centering, pre-bending, and rolling to be completed in a single loading process, reducing the need for flipping operations.

Equipment Features

Excellent pre-bending effect at the ends of the sheet metal, short straight edge length.

CNC system control, parameters can be repeatedly recalled, suitable for mass production.

Hydraulic drive, smooth operation, good forming consistency.

Compact structure, relatively convenient operation and maintenance.

W12 Series Hydraulic CNC Plate Rolling Machine

Mainly used in: pressure vessel and storage tank manufacturing, petroleum and chemical equipment, boilers and heat exchangers, wind turbine towers and various steel structures, shipbuilding and engineering machinery manufacturing, and environmental protection equipment industries. This equipment is suitable for rolling various conventional metal plates, including carbon steel plates, stainless steel plates, aluminum plates, and various alloy steel plates, and can meet the processing requirements for forming accuracy and stability under different working conditions.